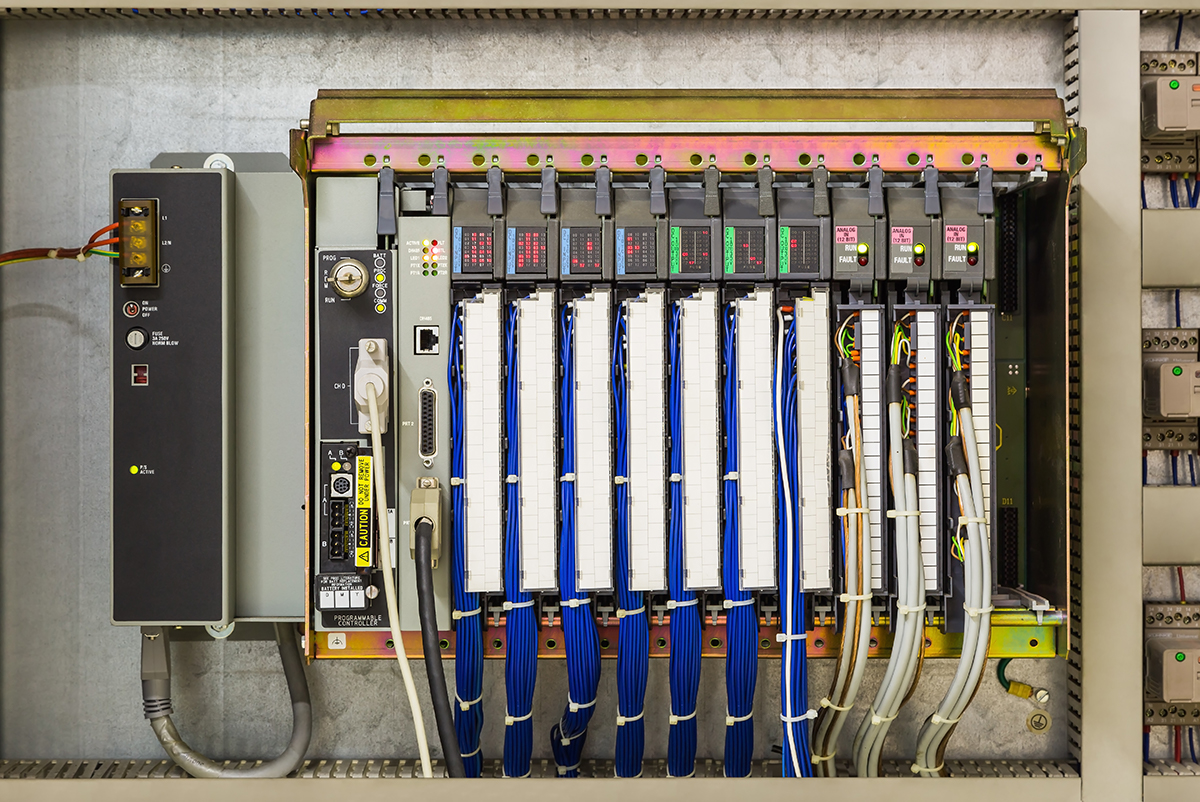

As legacy PLC-5 control systems and other PLC models continue to age, finding replacement parts is becoming more difficult and system maintenance costs are rapidly increasing. Migrating to a modern PLC platform offers significant improvements to overall equipment effectiveness (OEE), system reliability, parts availability, support, and process efficiency.When performing PLC upgrade services, we do our best to reduce downtime and costs by developing a thorough migration strategy using either a phased or total replacement approach. We also work to maintain the existing field wiring and enclosure footprint whenever possible.In addition, our PLC migration services include updating all system schematics, converting existing logic and programs to the new PLC platform, and rigorous testing to ensure proper operation and compatibility.