With hundreds of control systems integrators to choose from, these are some of the reasons why Process Solutions is the right choice for your project.

Our established procedures ensure consistent quality, prevent delays and miscommunications, and streamline project execution.

Starting from receipt of a purchase order, we schedule a kick-off meeting to clearly define the scope of work and client requirements. During the kick-off meeting we will also establish a project timeline and schedule.

During the engineering phase of a project, we utilize project management applications for team collaboration, work progress tracking, and to ensure every detail is accounted for. At various stages, design reviews are conducted by a Senior-level Engineer to check for compliance with project requirements and regulatory standards.

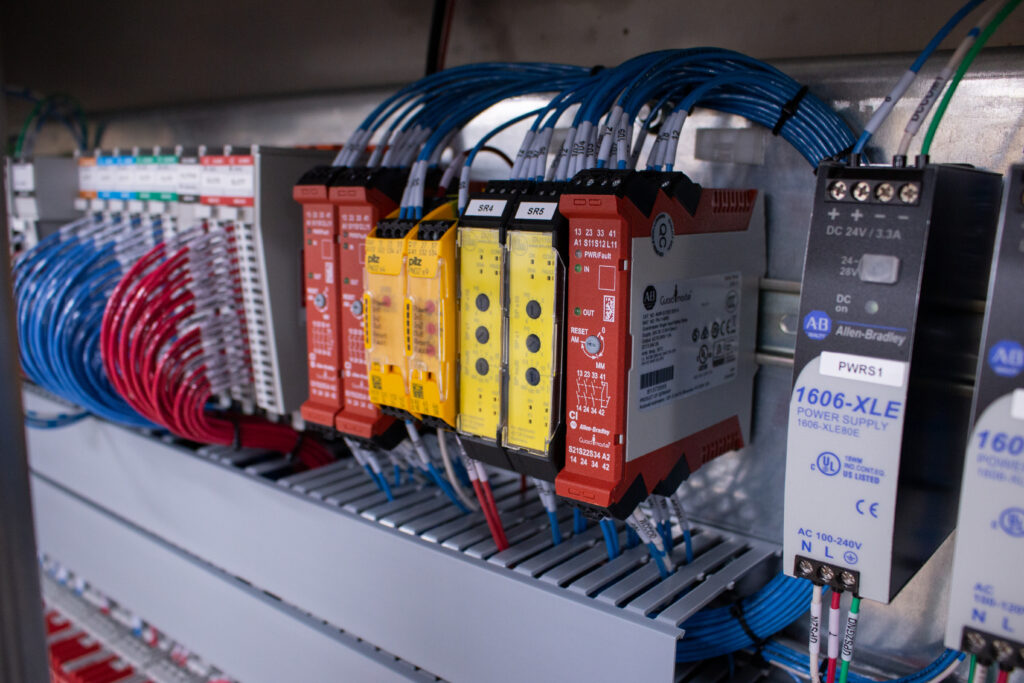

During production, we thoroughly inspect every panel and line of code to ensure quality and compliance and to verify proper functionality.