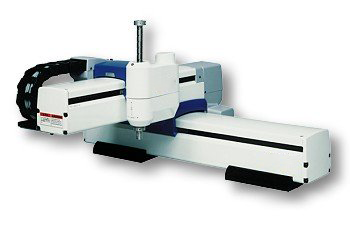

Cartesian robots, which are also called linear robots or gantry robots, are industrial robots that work on three linear axes that use the Cartesian Coordinate system (X, Y, and Z), meaning they move in straight lines on 3-axis (up and down, in and out, and side to side). Cartesian robots are a popular choice due to being highly flexible in their configurations, giving users the ability to adjust the robot’s speed, precision, stroke length, and size. Cartesian Robots are one of the most commonly used robot types for industrial applications and are often used for CNC machines and 3D printing.