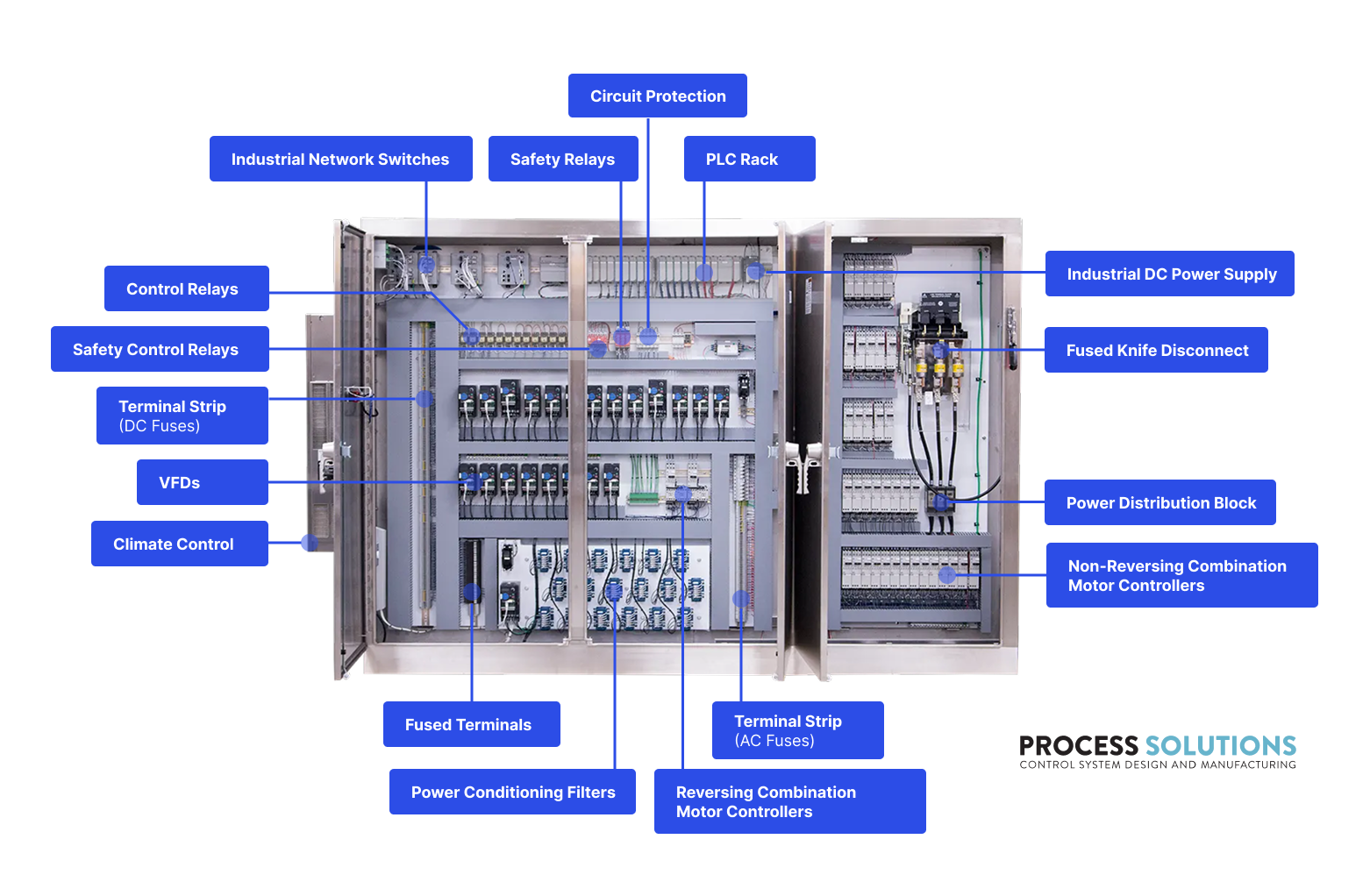

Industrial control panels contain dozens of core components that work together to power, protect, control, and communicate with your equipment. Understanding what each component does helps you make better decisions when specifying panels, evaluating vendors, and troubleshooting issues. This guide breaks down the key elements from the PLC rack and safety systems to motor controllers and climate control.

The Programmable Logic Controller is the brain of your control system. This ruggedized industrial computer monitors inputs from sensors and devices, processes that data through pre-programmed logic, and triggers outputs to control your equipment.

PLCs replaced hard-wired relay systems decades ago, and for good reason. They’re flexible, reliable, and can handle everything from simple on/off control to complex process automation. The rack itself provides the physical framework that holds the CPU, I/O modules, power supply, and communication interfaces.

When evaluating a control panel, pay attention to the PLC platform. Different manufacturers (Allen-Bradley, Siemens, Schneider) have different strengths, and the choice affects programming, spare parts, and long-term support.

Modern control panels rely on industrial Ethernet switches to connect everything together. These switches handle communication between PLCs, VFDs, HMIs, and other networked devices.

Industrial switches differ from office-grade equipment in important ways. They’re built for harsh environments with extended temperature ranges, vibration resistance, and DIN-rail mounting. They also support industrial protocols like EtherNet/IP, PROFINET, and Modbus TCP that require deterministic, low-latency communication.

The network switch acts as the central hub for data exchange within your control system. Without reliable communication, even the best PLC can’t coordinate equipment effectively.

If your panel controls motors, you’ll likely find Variable Frequency Drives inside. VFDs adjust motor speed and torque by varying the frequency and voltage supplied to the motor. Instead of running at full speed constantly, motors can operate at exactly the speed your process requires.

The benefits go beyond control. VFDs reduce energy consumption significantly since motors running at lower speeds use less power. They also provide soft-start capability, reducing mechanical stress on equipment and extending motor life. You’ll find VFDs controlling pumps, fans, conveyors, compressors, and countless other motor-driven systems.

Non-reversing combination controllers integrate a contactor, overload relay, and short circuit protection (circuit breaker or fuses) in one package. They’re used for motors that run in a single direction at full voltage, like pumps, fans, and compressors.

These assemblies simplify panel design by consolidating components and meet NEC Article 430 requirements for motor branch circuit protection.

Reversing combination controllers add the capability to change motor direction. They include two contactors wired to swap phase connections, plus the same overload and short circuit protection found in non-reversing units.

You’ll find these controlling conveyors, cranes, hoists, and other equipment that needs to run forward and backward.

These assemblies simplify panel design by consolidating components and meet NEC Article 430 requirements for motor branch circuit protection.

Control relays are specialized devices designed for safety-critical functions like emergency stops, safety gate monitoring, and light curtain supervision. Unlike standard relays, safety relays use redundant contacts and self-monitoring circuits that detect internal faults.

When you press an e-stop, safety relays ensure the system actually stops, even if a component has failed. These components help meet functional safety standards like ISO 13849 and ensure that safety functions perform reliably when needed.

Safety control relays provide additional relay contacts for safety circuits. They often work alongside safety relays to expand the number of safety outputs or provide isolation between safety and control circuits.

You’ll typically see these used when the main safety relay doesn’t have enough output contacts for all the devices that need to be controlled during a safety event.

Circuit breakers and fuses guard against short circuits and overcurrent conditions. These devices are your first line of defense when something goes wrong electrically.

The type and rating of protection devices directly affects your panel’s Short Circuit Current Rating (SCCR), which must meet or exceed the available fault current at your installation point per NEC Article 409.

The fused knife disconnect provides a visible means of disconnecting power to the entire panel. When the knife blades are open, you can visually confirm that power is disconnected before performing maintenance.

The integrated fuses provide additional overcurrent protection at the panel’s main feed. This component is often required by code as the main disconnecting means.

Fused terminals combine connection points with overcurrent protection in a single component. They protect individual circuits and simplify troubleshooting by isolating faults to specific branches.

When a fuse blows on a fused terminal, you know exactly which circuit has the problem without tracing wires throughout the panel.

Power conditioning filters suppress electromagnetic interference (EMI) and radio frequency interference (RFI) on power lines. This matters because VFDs, motors, and other equipment generate electrical noise that can disrupt sensitive electronics like PLCs.

EMI filters work both directions: they prevent external noise from entering the panel and block internally generated noise from affecting other equipment.

The DC power supply converts incoming AC voltage to the DC power that PLCs, sensors, and other control devices require. Most industrial control components operate on 24V DC which has become the industry standard.

The power supply must be sized to handle both the steady-state current draw and the inrush current when devices start up.

Power distribution blocks are machined aluminum or copper components that split large incoming power feeds into smaller conductors. They take the main feeder wires and distribute power safely to individual branch circuits throughout the panel.

You’ll typically see separate blocks for AC and DC distribution.

Terminal strips provide organized connection points throughout the panel. DC terminal strips (often with fuses) distribute converted power from internal power supplies to components requiring DC voltage. AC terminal strips handle alternating current distribution.

Both types allow for neat, organized wiring and easier troubleshooting. They also serve as the interface point where field wiring connects to internal panel wiring.

Electronic components generate heat, and that heat can shorten equipment life or cause failures. The climate control system maintains optimal operating temperatures inside the enclosure.

Depending on the application, climate control might include filter fans that pull cooler ambient air through the enclosure, air-to-air heat exchangers for environments where outside air can’t enter, or air conditioners for high heat loads or hot ambient conditions. Some panels also include heaters to prevent condensation in cold or humid environments.

Every 10°C rise above rated operating temperature can cut component life in half. Proper thermal management isn’t optional. It’s essential for reliability.

These components don’t operate in isolation. When you press a start button, the PLC receives the input signal, checks safety relay status, and sends commands through the network switch to VFDs and motor controllers. Circuit protection stands ready to interrupt power if something goes wrong. The DC power supply keeps control circuits running while the climate control system maintains safe operating temperatures.

Every component in a control panel affects safety, efficiency, and long-term reliability. When you understand what’s inside, you can have more productive conversations with vendors, catch specification issues before they become installation problems, and troubleshoot more effectively when something goes wrong.

The best control panels aren’t just assembled from quality components. They’re designed by engineers who understand how those components work together in your specific application.