Airixa integrates with refrigeration equipment and instrumentation to monitor, control, and optimize your entire refrigeration process.

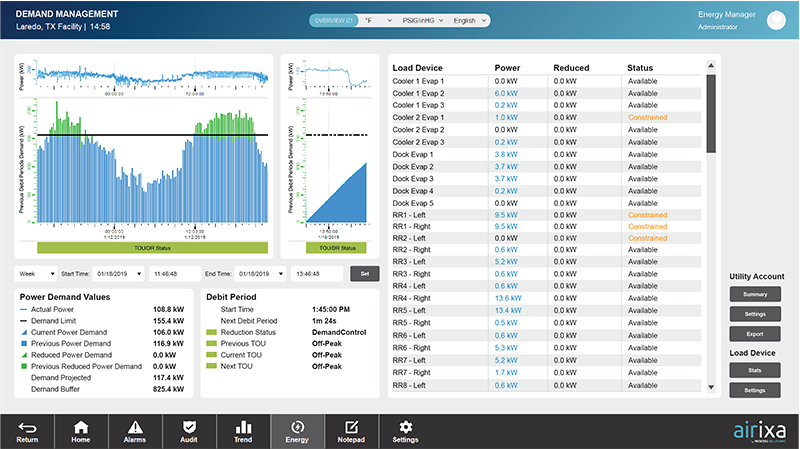

Limit demand spikes during peak utility rate periods and generate additional revenue with demand response rebates and incentives.

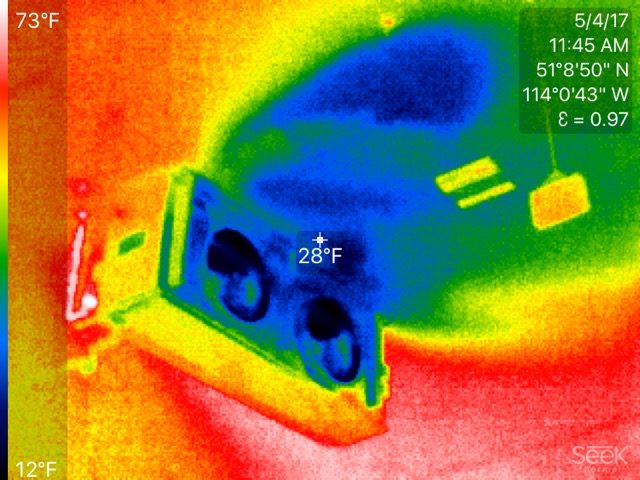

Efficiency measures, including VFD speed control for evaporator fans, improve system efficiency without compromising performance.

Object-oriented software design allows for quickly adding new equipment to Airixa without re-engineering the entire system.

Electricity bills include demand charges measured in kilowatts (kW) that are determined by the peak demand within a billing period. Typically, the demand charge is calculated by the highest average kW during a set time period and can account for up to 10-40% of a business’s utility bill.

Through sophisticated load reduction capabilities, including equipment start-up sequencing, user-selected load reduction priorities, adaptive power demand limits, and load shifting algorithms, Airixa can significantly reduce your energy bill by limiting energy demand spikes during peak periods when utility rates are highest. Many US companies that implement demand response can also generate additional revenue through rebates and incentives offered by utility providers.

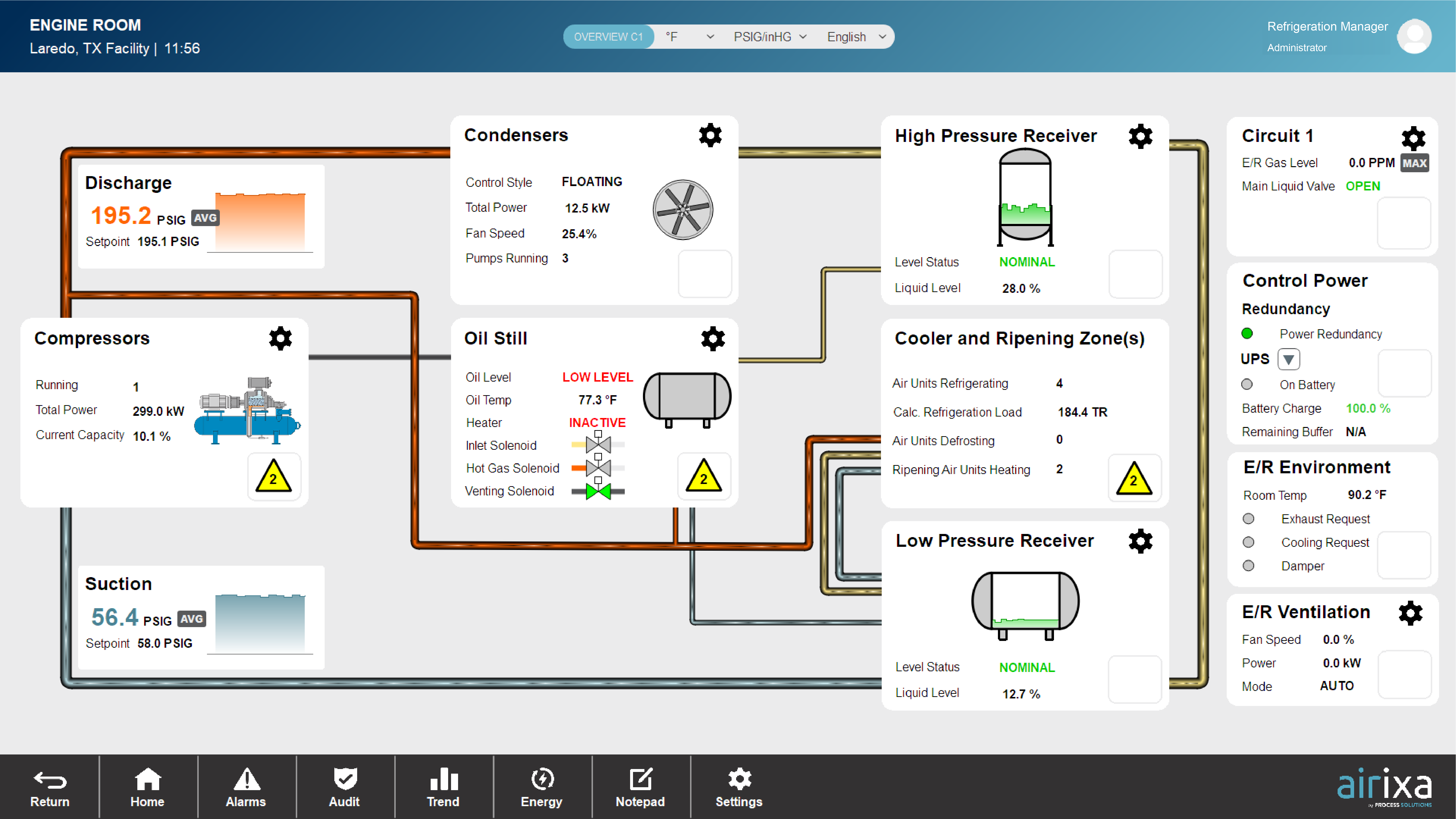

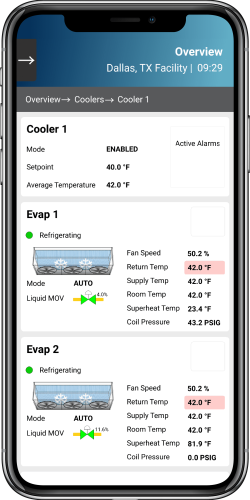

Refrigeration systems need to operate reliably 24/7 to prevent the loss of perishable food products. With Airixa’s supervisory control and data acquisition (SCADA) software, companies can monitor the status, health, and performance of their entire refrigeration system from both the plant and enterprise levels.

Through direct integration with PLCs and connected instrumentation, Airixa can directly control connected equipment and collect real-time data to generate informative dashboards with graphic visualization of system information, including live trends, data feeds, active alarms, and machine operating status.

Installations Across North & South America

With installations in the United States, Canada, Mexico and Peru, Airixa controls over 2,000,000 sq. ft. of production space, including 152 fruit and vegetable ripening rooms.