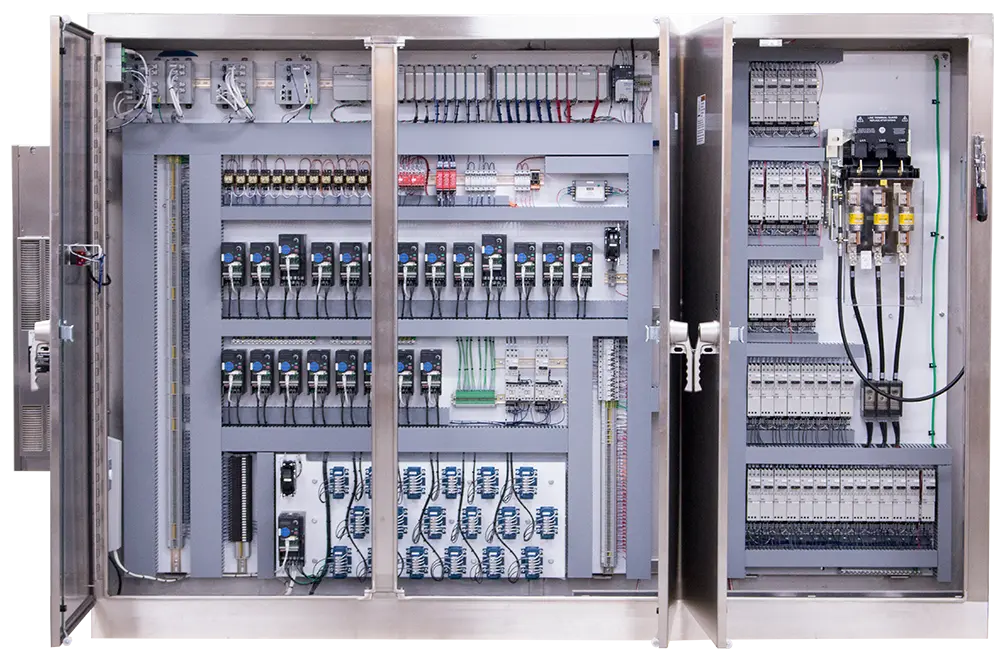

Process Solutions provides custom UL control panel design and fabrication services for almost any industry or application. We work closely with our clients to understand their requirements and deliver tailored solutions to improve process control and maximize productivity.