Supervisory Control and Data Acquisition, or SCADA, is a hardware and software system used to monitor and automate the control of industrial processes and machines. For many manufacturers and municipalities, SCADA systems are a critical component of the overall production process and are required to be secure, efficient, and capable of performing all necessary tasks. Over time, a SCADA system can become outdated and unsupported, lack functionality and features, present security risks, and be difficult to scale. These are the four reasons why you should upgrade your SCADA system:

System Support and Compatibility

An outdated SCADA system will often be unsupported by the manufacturer and be incompatible with modern controls hardware. Without manufacturer support, an outdated SCADA system will no longer receive necessary security patches or system updates, which can lead to extended downtimes during equipment failures, and a higher risk for cyber-attacks. Additionally, it can be challenging to find replacement parts for the outdated controls hardware, as well as increasingly expensive.

Unlock Greater Functionality and Features

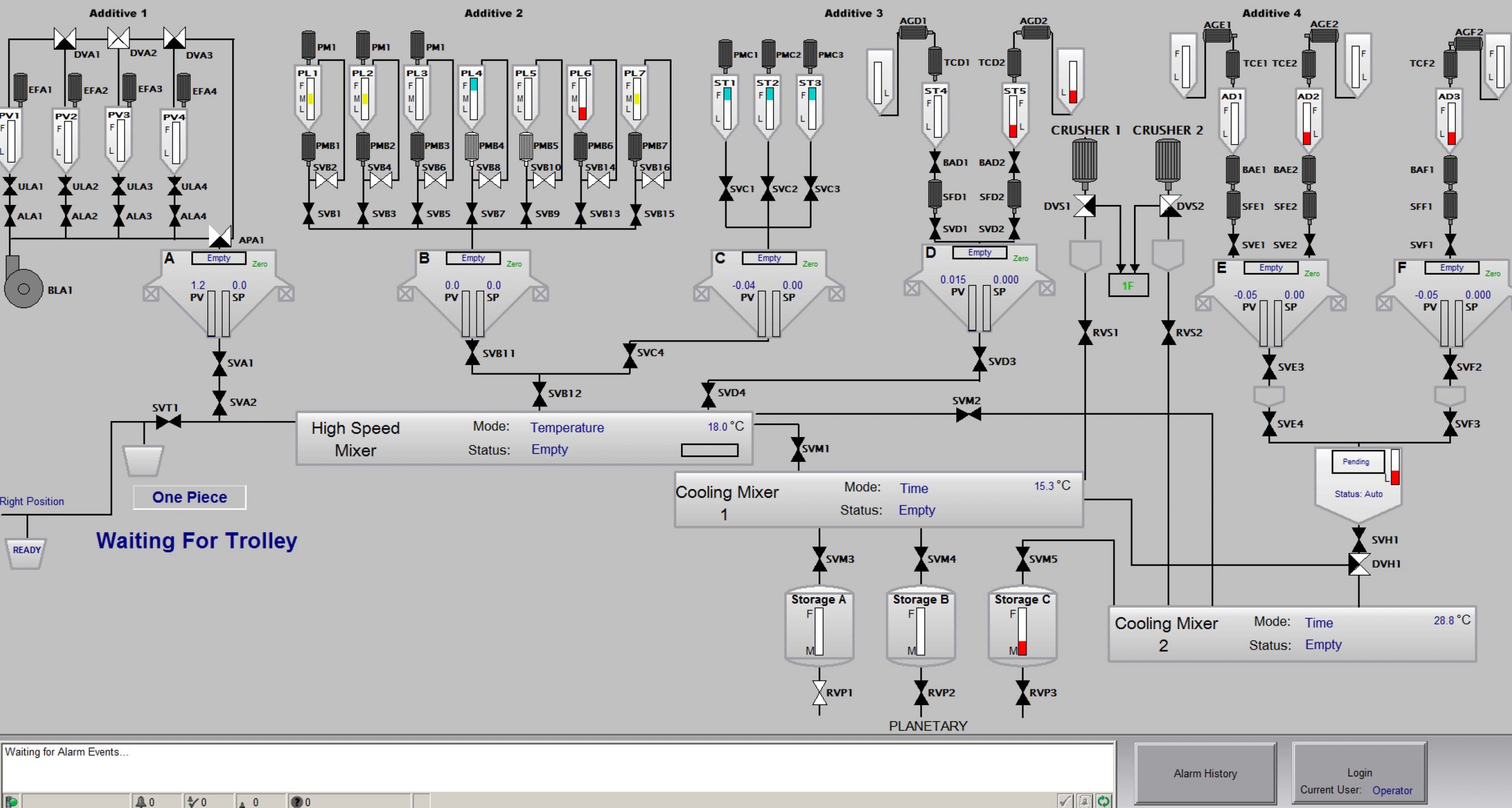

Older SCADA systems may not have the same level of functionality and features that a new SCADA system can offer. For example, modern SCADA systems include improved graphics that provide more contextual information and greater situational awareness while reducing distractions by eliminating busy interfaces and animations in favor of intuitive and clean displays.

Additionally, a new SCADA system will often have increased connectivity and allow for integration with complementary programs, such as an ERP system, CRM, SQL databases, and modern HMI software. Finally, technological advances and processing improvements provide the opportunity to future proof your systems and incorporate IIOT data, machine learning, and artificial intelligence capabilities into your manufacturing.

Improve System Security

Outdated SCADA systems are vulnerable to data invasions, and likely can’t comply with newer security standards, such as encryption, two-step authentication, and secure remote access. SCADA security has drastically improved in recent years to reduce or eliminate both physical and cyber vulnerabilities. Upgrading to a modern SCADA system will allow you to take advantage of the new security capabilities and ensure you are protected from attacks.

Scalability and Future Proofing

Modern SCADA systems can be developed using object-oriented programming. This programming technique entails a template-based system design with easily manageable blocks of code representing various objects or equipment. As your manufacturing grows, new code blocks can be added quickly and inexpensively, allowing your SCADA system to grow with you. Furthermore, once a system template has been created, it can be copied and reused for each new facility, significantly reducing development time and costs.

About Process Solutions

Located near Seattle Washington, Process Solutions is the Northwest’s largest control systems integrator. With 30+ years in business and over 100 engineers and technicians on staff, Process Solutions has the experience and capacity to take on almost any automation project. Process Solutions provides a wide range of control system services, including electrical control panels, PLC and HMI programming, robot system integration, energy management and refrigeration systems, SCADA software design, and machine monitoring software.