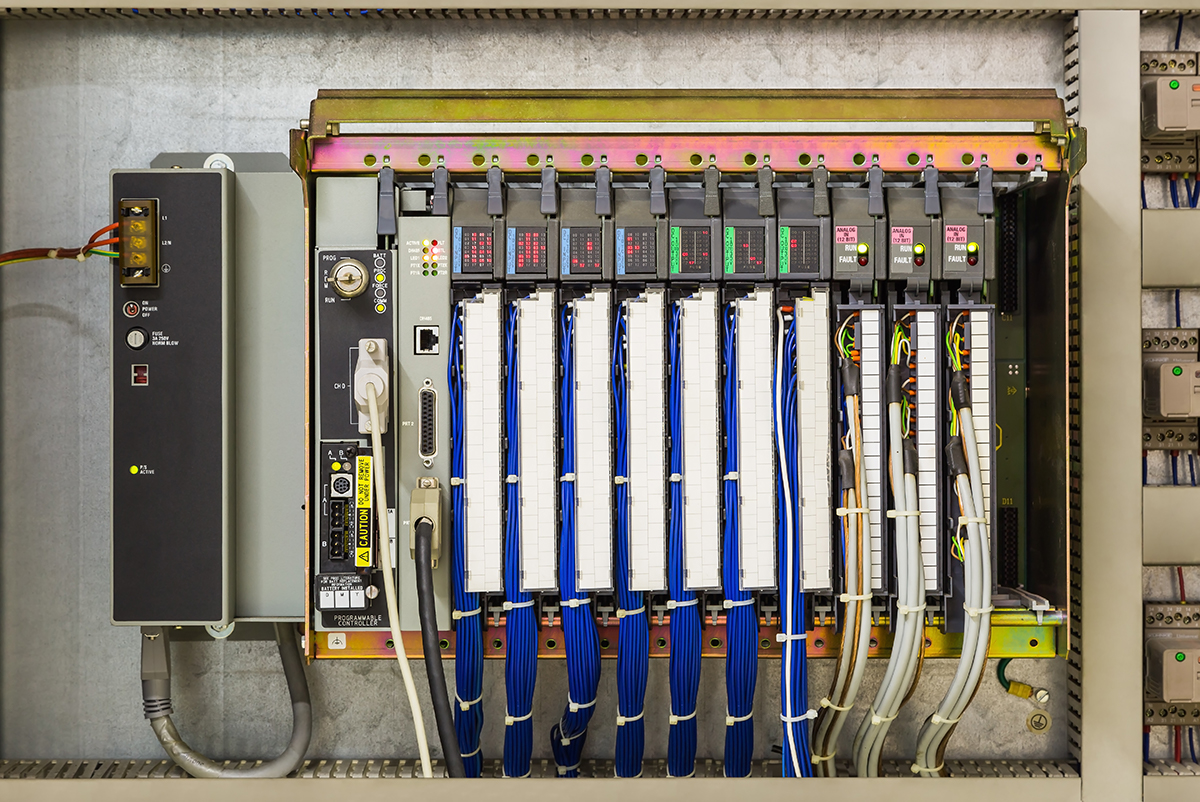

Introduced in 1986, the PLC-5 was one of the first PLCs that could be programmed by a personal computer. According to the Rockwell Automation website, the PLC-5 boasts one of the largest install bases of any control platform. However, in 2017 Rockwell officially discontinued the platform. So, what should manufacturers who are still operating on a PLC-5 do when their controllers begin to break down? Our recommendation is to migrate to one of the many modern controls platforms available on the market.

Why You Should Modernize Your PLC Control System

Every manufacturer should consider what the impact would be if their PLC-5 stopped working and the necessary spare parts to restore operations are unavailable. With the PLC-5 now discontinued, new parts are no longer available from Rockwell or many third-party vendors. This means manufacturers still operating on a PLC-5 run the risk of system failures and lengthy downtimes while they scavenge the used market for replacement parts. By migrating to a modern control platform, manufacturers can receive greater technical support from either control systems integrators or suppliers, as well as reduce or eliminate downtime with fast delivery of replacement parts.

Another advantage of upgrading to a modern controls platform is the significantly increased performance. The new series of controllers have more processing power and can be connected to modern IT networks. Furthermore, new PLCs are easier to integrate with MES and ERP systems, providing the ability to collect data, generate detailed production reports, and monitor equipment in real-time.

New controls hardware is also more flexible with the ability to support a wide range of I/O and communications modules. These modules make it easier and more cost effective to scale a new system to any manufacturing environment or application.

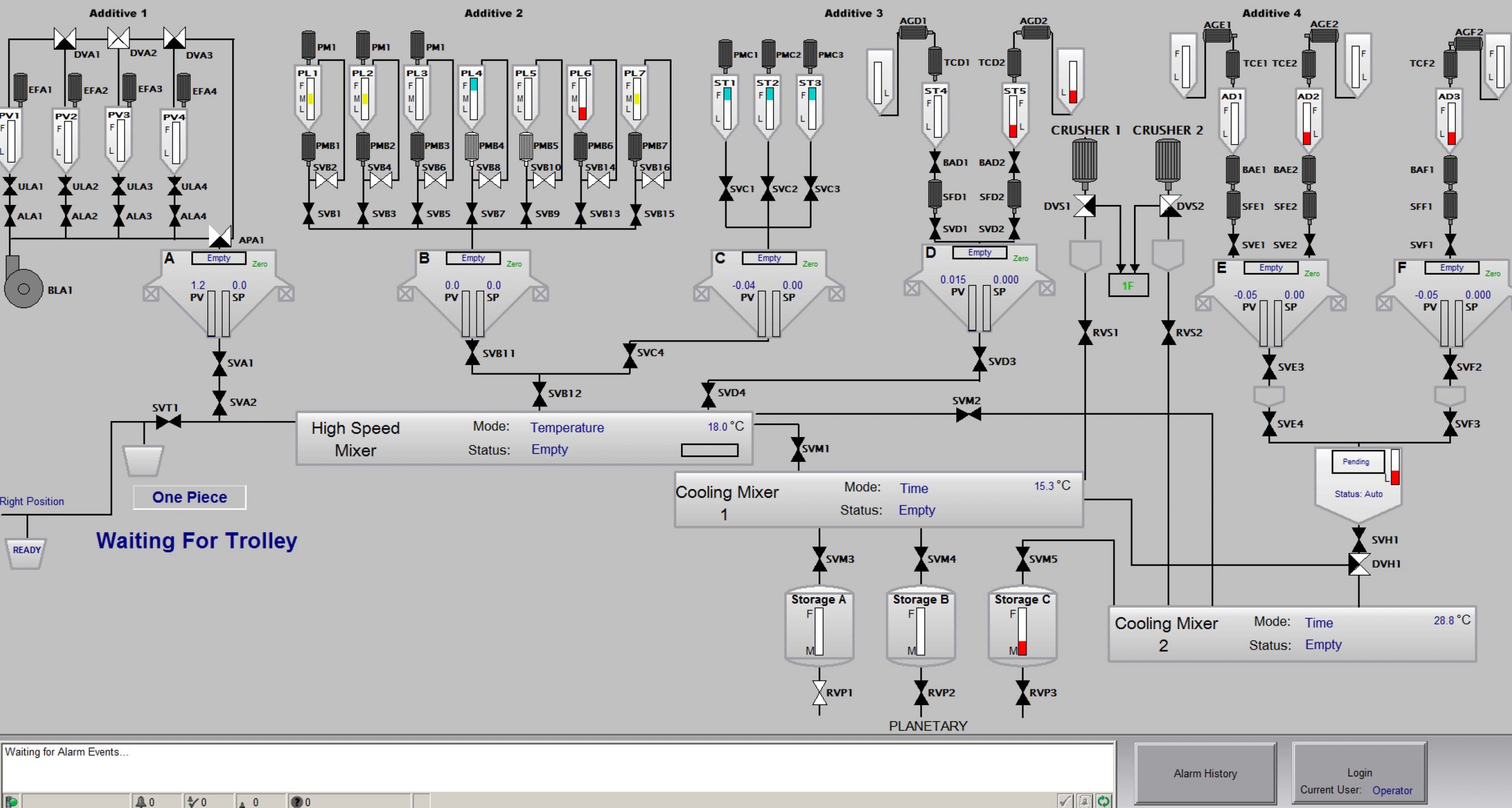

Modern PLCs also come with new software programs that can provide more diverse feature sets and enhanced graphics for HMIs. The new software programs also simplify diagnosing and troubleshooting system faults.

Another advantage of upgrading to a modern controls platform is the significantly increased performance. The new series of controllers have more processing power and can be connected to modern IT networks. Furthermore, new PLCs are easier to integrate with MES and ERP systems, providing the ability to collect data, generate detailed production reports, and monitor equipment in real-time.

New controls hardware is also more flexible with the ability to support a wide range of I/O and communications modules. These modules make it easier and more cost effective to scale a new system to any manufacturing environment or application.

Modern PLCs also come with new software programs that can provide more diverse feature sets and enhanced graphics for HMIs. The new software programs also simplify diagnosing and troubleshooting system faults.

Consulting a Control Systems Integrator

Migrating to a modern control system can be a complicated task and is typically best handled by an experienced control systems integrator that can design a custom system to fit your application. Additionally, a control system integrator will have the knowledge, tooling, and resources to complete the task quickly and with high-quality parts, which can result in less downtime and mitigates the chances of equipment failure.

At Process Solutions, we offer start-to-finish PLC migration services. We will conduct an on-site assessment, develop a migration plan, design and build the new system, and handle all the on-site start-up and commissioning services. Process Solutions will also go the extra step to ensure your new system is optimized to improve the efficiency and performance of your operations versus just replacing the legacy system with new parts.

At Process Solutions, we offer start-to-finish PLC migration services. We will conduct an on-site assessment, develop a migration plan, design and build the new system, and handle all the on-site start-up and commissioning services. Process Solutions will also go the extra step to ensure your new system is optimized to improve the efficiency and performance of your operations versus just replacing the legacy system with new parts.

Phased Migration Approach

When helping our clients migrate to a new PLC system, we typically follow a phased approach to changing out the hardware and software components:

- The first phase of the process consists of converting the old PLC-5 program code to operate on the new controls hardware. With automated software code conversion tools available, this phase is usually straightforward and quick to complete. Once the code has been converted, we put it through our standardized testing procedure to ensure proper functionality and to eliminate any bugs or errors.

- Once the program code has been converted and thoroughly tested, we move on to replacing the PLC-5 controller with a new processor and I/O cards. Whenever possible, we take care to preserve the existing field wiring to reuse with the new controller. By reusing the existing field wiring, we can save a significant amount of time on labor and costs.

- With the new PLC in place, we can replace any old HMIs with new HMI models that provide options for enhanced graphics and expanded feature sets.

Let's Get Started on Your PLC Migration Project

Process Solutions has over 30 years of experience in managing control system projects for numerous industries and applications. We pride ourselves on our ability to minimize downtime and design control systems that are easy to use, efficient, and reliable. Using a phased approach, Process Solutions will help you upgrade your operation to the latest controls technology while giving you the peace of mind that your project will be done right, and your system will be supported for years to come.

About Process Solutions

Located near Seattle Washington, Process Solutions is the Northwest’s largest control systems integrator. With 30+ years in business and over 100 engineers and technicians on staff, Process Solutions has the knowledge, experience, and capacity to take on almost any automation project. Process Solutions provides a wide range of automation services, including electrical control panels, PLC and HMI programming, Industrial and collaborative robots, energy management and refrigeration systems, SCADA systems, and data analytics software systems. For more information, please visit www.processsolutions.com.

READY TO CHAT?

Please fill in your contact and project information and a Process Solutions representative will be in touch with you shortly.