Modern manufacturers are making data-driven decisions to help improve their production output, eliminate waste, and reduce operating costs. However, to collect data from their equipment and lines, manufacturers often need to purchase specific hardware components and software licenses. The problem for many manufacturers is they don’t have the available budget to acquire the necessary hardware and software components, leaving them unable to collect the data they need.

To provide manufacturers with a powerful and cost-effective solution for collecting production data, Process Solutions developed DAQuery Machine Monitoring Software. DAQuery is a custom software platform designed to communicate with industrial or commercial networked devices, collect and store live data, and transform that data into actionable information. DAQuery is also designed to be scalable to work within any manufacturing environment.

Transforming Manufacturing Data Into Actionable Information

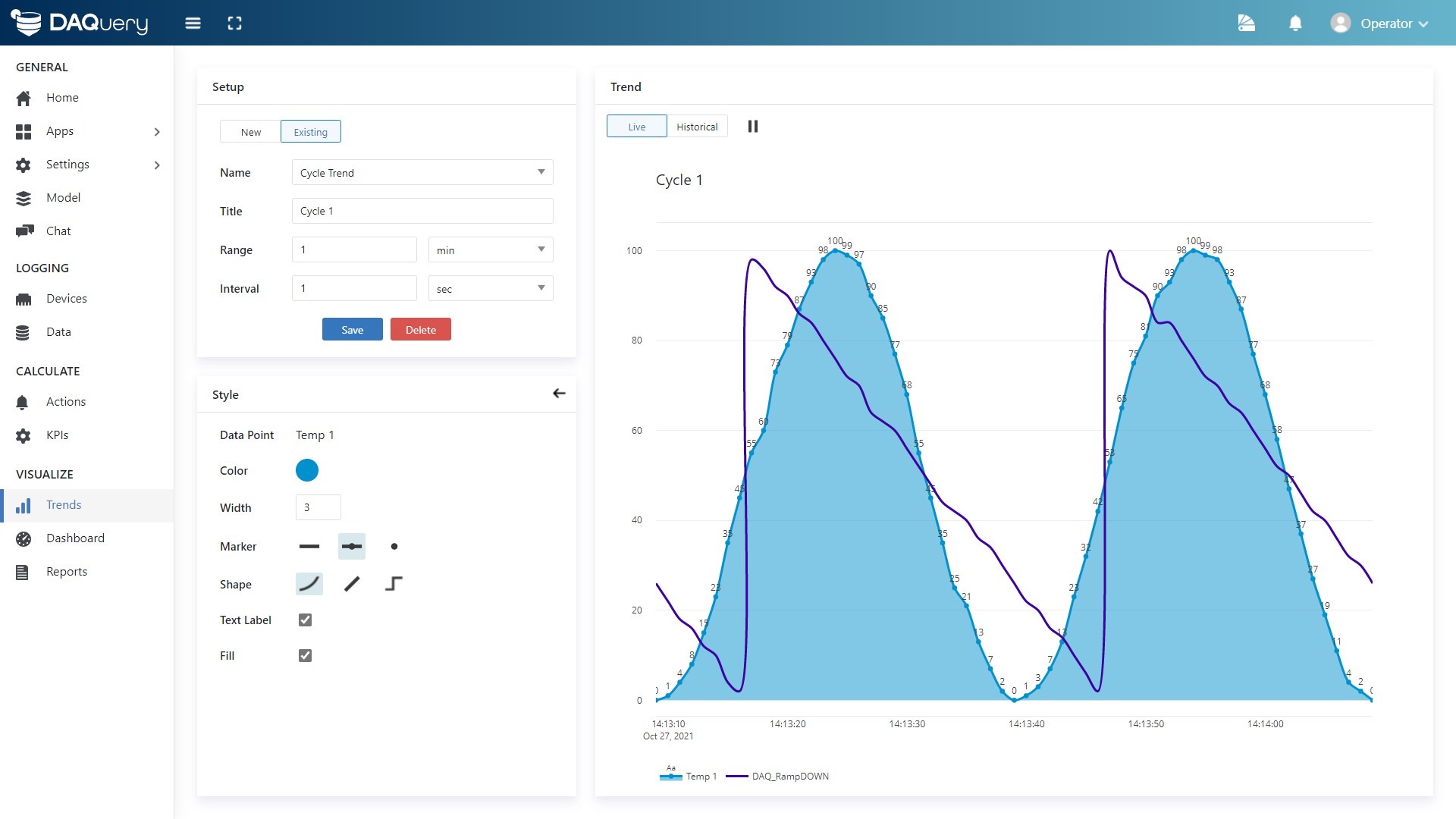

What makes DAQuery unique, is the system’s ability to collect raw production data directly from your equipment, eliminating the need for a PLC and software licenses. DAQuery then transforms the collected data into actionable information, such as production throughput, batch recipe information, alarming and notifications, recipe management, audit trails, overpack percentage, and other KPI reports. All DAQuery’s reports are exportable to .CSV, .XLSX, .PDF, .MHTML, .DOCX, .TIF, .PP, and .XML file formats, and can be configured to include user-selected report parameters, such as a range of time or equipment type. Overall, DAQuery acts as a decision and report engine for your plant.

Live Data Feeds

OEE Metrics

OEE metrics are another useful tool manufacturers can access through DAQuery Machine Monitoring Software. With OEE metrics, manufacturers can gain valuable insight into both the percentage of manufacturing time that is actually productive and how to systematically improve their production process. When analyzed and acted upon, OEE metrics help identify where waste is occurring in the production process, benchmark progress, and increase productivity.

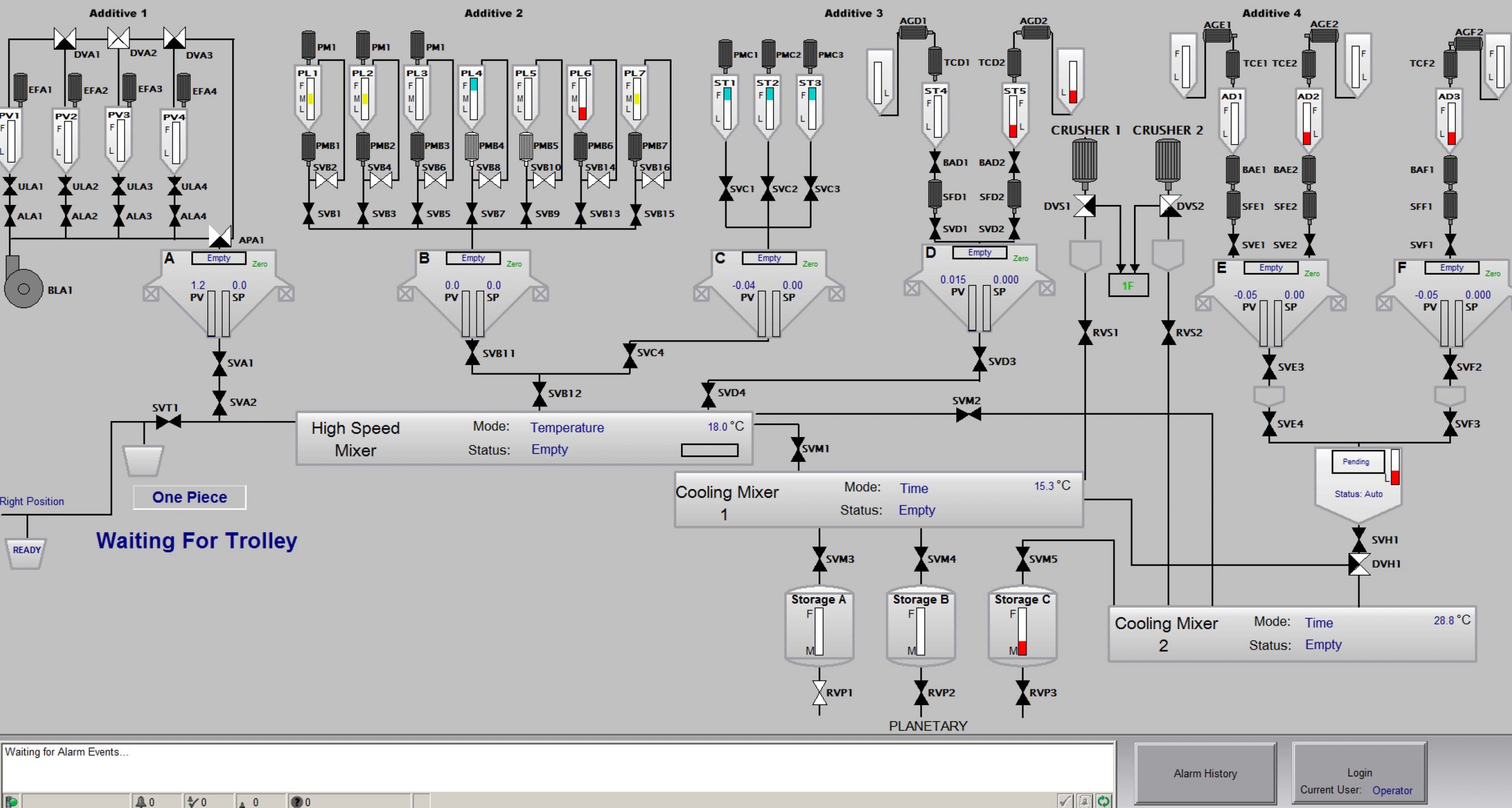

PLC Connectivity

For facilities with PLCs and other controls hardware already installed, DAQuery includes a PLC data logging protocol that does not require the use of expensive third-party software. This protocol allows DAQuery to log data from connected PLCs and seamlessly store the data in any database.

Implementing DAQuery Machine Monitoring Software

When implementing DAQuery into your facility, Process Solutions’ team of software engineers will work with you to tailor the system to fit your manufacturing environment. Our engineers can also configure DAQuery’s dashboards to display your most important data front and center. For more information about DAQuery Machine Monitoring Software or to schedule a live software demo, please visit www.processsolutions.com/DAQuery.

About Process Solutions, Inc.

Located near Seattle Washington, Process Solutions is the Northwest’s largest control systems integrator. With 30+ years in business and over 100 engineers and technicians on staff, Process Solutions has the knowledge, experience, and capacity to take on almost any automation project. Process Solutions provides a wide range of automation services, including custom electrical control panels, PLC and HMI programming, industrial and collaborative robots, energy management and refrigeration systems, custom SCADA systems, and Machine Monitoring software. For more information, please visit www.processsolutions.com.