The Problem:

The United States Coast Guard requires the City of Tacoma to perform regularly scheduled updates to the PLC control system that operates the Hylebos drawbridge. These scheduled updates are required to ensure the bridge functions properly and the critical waterway always remains accessible. Should the waterway ever become inaccessible due to a bridge malfunction, the City can be subject to paying fines until the waterway is reopened.

When the drawbridge control system came due for updates in 2021, the City of Tacoma turned to Process Solutions after receiving a positive referral from a local engineering firm. Upon inspection by a Process Solutions Engineer, it was determined that the existing SLC500 series controllers were no longer compatible with the most recent software updates and required replacement. In addition, the City expressed interest in upgrading to the latest PLC equipment to better futureproof the bridge’s controls.

When the drawbridge control system came due for updates in 2021, the City of Tacoma turned to Process Solutions after receiving a positive referral from a local engineering firm. Upon inspection by a Process Solutions Engineer, it was determined that the existing SLC500 series controllers were no longer compatible with the most recent software updates and required replacement. In addition, the City expressed interest in upgrading to the latest PLC equipment to better futureproof the bridge’s controls.

The Solution:

Process Solutions sent a tandem of Senior Engineers to coordinate with a team of electricians from Prime Electric to replace the existing SLC500 series controllers with a redundant processing pair of ControlLogix PLCs. Process Solutions performed the PLC and HMI programming and system commissioning, while Prime Electric removed the old PLC system and performed the installation and wiring of the new system.

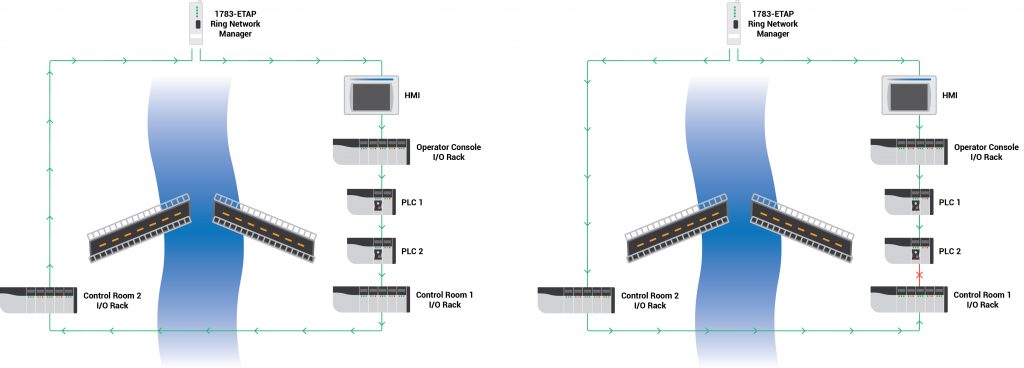

Each of the new ControlLogix PLCs include a RM-2 redundancy module that enables the redundant processor to seamlessly take over if the other fails. Both PLC racks and an accompanying I/O rack are installed in a control room on one end of the bridge, while another I/O rack is installed in a second control room positioned on the opposite end of the bridge. As part of the project, Process Solutions and Prime Electric also upgraded both control room’s I/O racks and a third I/O rack installed in the operator console to the ControlLogix I/O platform.

To bring all of the bridge’s controls onto the same tag-based platform, Process Solutions and Prime Electric upgraded a separate pair of existing MicroLogix PLCs to CompactLogix. The CompactLogix PLCs control the actual raising and lowering movement of the bridge. Once the traffic gates are down, traffic signals are red, and the bridge center locks are unlocked, the ControlLogix auto PLC system sends a hardwired signal to the CompactLogix PLC to raise or lower the bridge. In the event of an auto PLC malfunction, the operators can also manually raise or lower the bridge using these same processors.

In addition, Process Solutions and Prime Electric upgraded the existing ControlNet-based PanelView 6 HMI to a new Ethernet-based 10” PanelView Plus 7 interface. The HMI is dedicated to alarming purposes when certain events occur, such as if the brakes failed to release or engage.

To bring all of the bridge’s controls onto the same tag-based platform, Process Solutions and Prime Electric upgraded a separate pair of existing MicroLogix PLCs to CompactLogix. The CompactLogix PLCs control the actual raising and lowering movement of the bridge. Once the traffic gates are down, traffic signals are red, and the bridge center locks are unlocked, the ControlLogix auto PLC system sends a hardwired signal to the CompactLogix PLC to raise or lower the bridge. In the event of an auto PLC malfunction, the operators can also manually raise or lower the bridge using these same processors.

In addition, Process Solutions and Prime Electric upgraded the existing ControlNet-based PanelView 6 HMI to a new Ethernet-based 10” PanelView Plus 7 interface. The HMI is dedicated to alarming purposes when certain events occur, such as if the brakes failed to release or engage.

Finally, a device-level ring network was installed that requires two breaks in the ring before the bridge controls become inoperable. The network operates through a 1783-ETAP ring manager, which has two ports for the network signal to pass through and can detect that a ring network is present. To prevent flooding the network, the ring manager shuts down one of its two ports so that the network signal can only travel in one direction. Anytime the ring manager detects that the ring is broken, the second port is automatically enabled, allowing the signal to travel in both directions up to the point of the break. This ensures network communications remain intact if the ring is ever broken.

The Result:

The Hylebos Bridge is now operated by the latest PLC technology with multiple redundancies to ensure the drawbridge always remains functional and the critical waterway remains accessible to shipping vessels. Additionally, the new system can be updated for many years into the future, ensuring the City of Tacoma stays in compliance with United States Coast Guard mandates.

Project Photo Gallery:

Operator console with the new ControlLogix I/O rack and PanelView Plus 7 HMI installed .

Old SLC500 Series I/O rack taken out of the operator console.

The new ControlLogix I/O rack installed in the operator console

Operator console backpanel

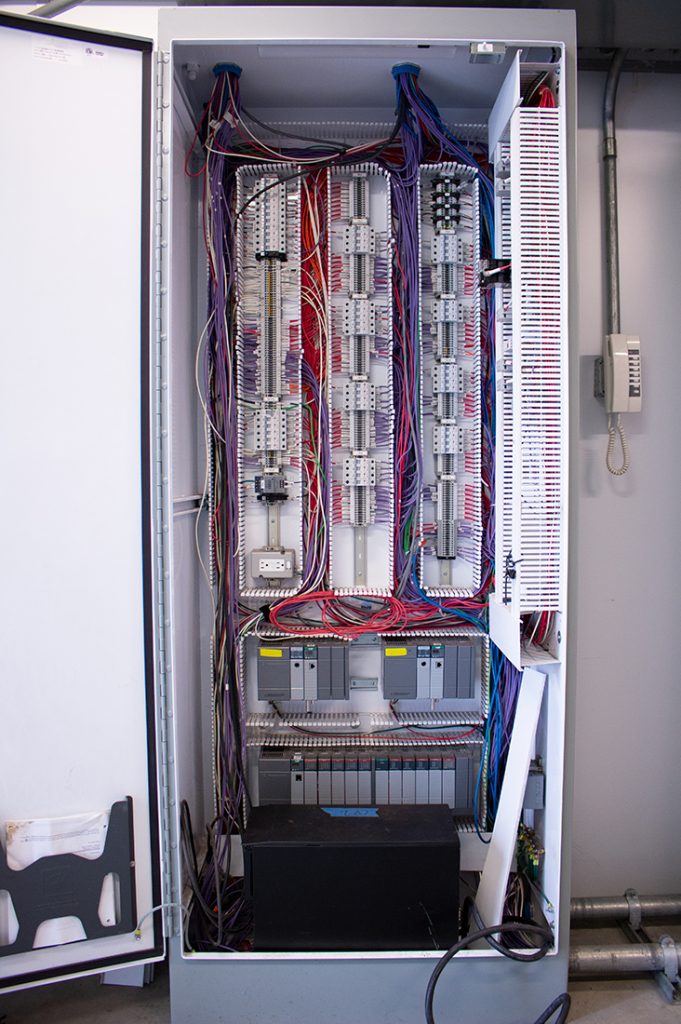

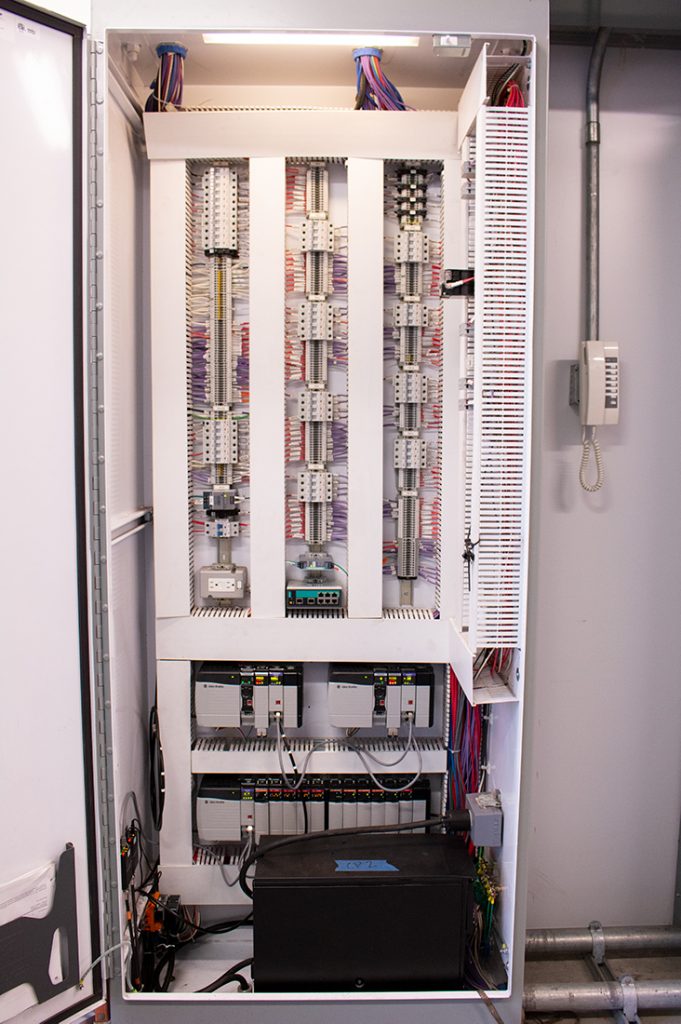

Control room with the new redundant processing pair of ControlLogix PLCs and accompanying I/O rack installed.

Prime Electric Electrician Wiring the new ControlLogix I/O rack

Redudant Processing Pair of ControlLogix PLCs

Manual bridge controls with the new CompactLogix PLC installed.

The existing MicroLogix PLC that was replaced by Process Solutions with a new CompactLogix controller.

New CompactLogix PLC for manual bridge controls.

Second control room with new ControlLogix I/O rack installed.

ControlLogix I/O rack

View from the operator station of the fully opened Hylebos Drawbridge

Side view of the fully open Hylebos Drawbridge

About Process Solutions, Inc.

Based near Seattle, Washington, Process Solutions is the Northwest’s largest control systems integrator. With a focus on providing industry-leading quality and service, Process Solutions offers a range of control system solutions, including UL control panel design and fabrication, PLC and HMI programming, SCADA integration, industrial refrigeration control systems, and machine monitoring software. Over its 34-year history, Process Solutions has successfully completed thousands of projects for end-users, OEMs, and government entities across industries and applications. With more than 100 engineers and technicians on staff combined with over 30,000 sq. ft. of engineering and production space, Process Solutions has the capacity and expertise to execute projects of almost any size or complexity.

About Prime Electric

Prime is one of the most prolific and successful electrical construction contractors on the west coast. With primary markets in the tech-centric regions of Seattle and Silicon Valley, Prime has extensive experience across all industry groups, and delivery models. For more information, please visit www.primee.com.