Your equipment vendor just sent back your purchase order because the enclosure specification doesn’t match what you actually need. We see this all the time, and the root cause is always the same: confusion between NEMA and IP ratings.

Both systems rate protection levels for electrical enclosures, but they measure completely different things. Understanding these differences prevents rejected equipment deliveries, budget overruns, and premature equipment failures that cost thousands in downtime.

How NEMA Ratings Work

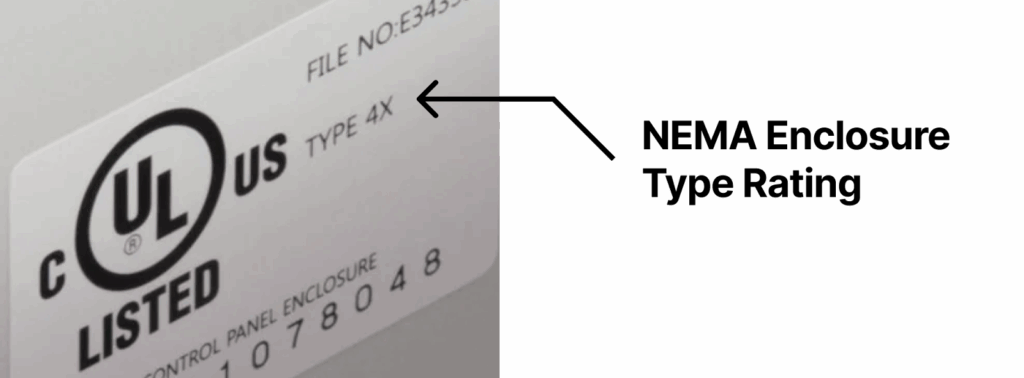

NEMA ratings focus on environmental withstand capability and corrosion resistance, developed specifically for industrial enclosures by the National Electrical Manufacturers Association. These standards test how well enclosures perform under real-world conditions like rain, dust, chemical exposure, and temperature extremes.

Common industrial ratings include NEMA 4, NEMA 4X, and NEMA 12, but the numbers don’t increase sequentially in terms of protection. NEMA 12 provides indoor protection against dust and dripping liquids, while NEMA 4 offers watertight outdoor protection, which means NEMA 12 actually provides less protection than NEMA 4 despite the higher number.

The “X” designation changes everything because a NEMA 4X rating includes all the protection of NEMA 4 plus corrosion resistance. This matters because corrosion testing is rigorous, requiring enclosures to undergo 1,200 hours of exposure to moist air containing carbon dioxide and sulfur dioxide, plus 800 hours of salt spray testing. They must also resist damage from ice forming on the exterior, making NEMA 4X enclosures the right choice for coastal facilities, chemical plants, biotech, pharma, food processing operations with aggressive washdown procedures, and anywhere salt air or corrosive gases are present.

The price impact is significant because adding the “X” designation increases enclosure costs by 25-40% compared to the base rating. Material requirements drive this premium since stainless steel costs more than carbon steel, and specialized gasket systems add to the total. NEMA 4X enclosures typically use stainless steel or corrosion-resistant plastics to meet these demanding requirements.

For water protection, NEMA 4 and 4X must withstand 65 gallons per minute from a 1-inch nozzle positioned 10-12 feet away for five minutes while remaining dust tight and maintaining functionality even when ice forms on the exterior. These aren’t just paper specifications but tests that replicate actual industrial conditions.

How IP Ratings Work

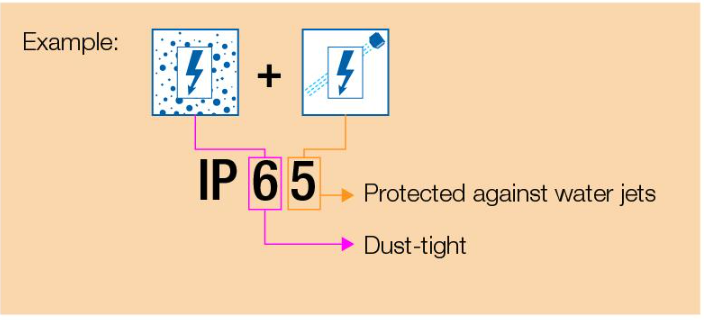

IP ratings take a different approach by measuring ingress protection from particles and moisture through a two-digit code created by the International Electrotechnical Commission. The first digit ranges from 0 to 6 and indicates solid particle protection, where a rating of 0 means no protection and a 6 means dust tight, verified through vacuum testing that pulls air through the enclosure without allowing dust penetration.

The second digit ranges from 0 to 9 and covers moisture protection, where a 0 provides no protection, a 6 protects against powerful water jets, a 7 protects against temporary water immersion up to 1 meter, and an 8 protects against continuous immersion under manufacturer-specified conditions. IP67 is a common rating that breaks down simply: the 6 means dust tight and the 7 means the enclosure can handle temporary immersion in water up to 1 meter deep for 30 minutes. You’ll see IP67 on smartphones, outdoor sensors, and industrial equipment that might encounter wet conditions.

Here’s a quick reference table for the different ratings:

| First Numeral | Protection Against Solid Objects | Second Numeral | Protection Against Water |

|---|---|---|---|

| 0 | No protection | 0 | No protection |

| 1 | Objects ?50mm diameter | 1 | Vertically falling water drops |

| 2 | Objects ?12.5mm diameter | 2 | Water drops (enclosure tilted 15°) |

| 3 | Objects ?2.5mm diameter | 3 | Spraying water |

| 4 | Objects ?1.0mm diameter | 4 | Splashing water |

| 5 | Dust-protected | 5 | Water jets |

| 6 | Dust-tight | 6 | Powerful water jets |

| 7 | Temporary water immersion | ||

| 8 | Continuous water immersion | ||

| 9 | High-pressure/temperature water jets |

IP ratings apply broadly across industries because the same standard rates robot lawnmowers, consumer electronics, marine equipment, and industrial control panels. This universality makes IP ratings useful for global projects and products that cross multiple markets, but the critical limitation is scope.

IP ratings only measure sealing capability against particles and water without testing corrosion resistance, ice formation, or temperature extremes. An IP66-rated enclosure protects against powerful water jets at 100 liters per minute and 100 kPa pressure from a 12.5mm nozzle, but it may corrode rapidly in salt air because corrosion isn’t part of the test.

One more important detail: IP ratings aren’t cumulative beyond IPX6, which means an enclosure rated IP67 for immersion might fail an IP66 jet test because the tests measure different things. If you need both protections, the enclosure must be tested and rated for both, shown as IP66/IP67.

Why These Systems Aren’t Interchangeable

The test methodologies differ significantly because NEMA 4X water testing uses 240 liters per minute at 31 kPa from 3 meters away, while IP66 uses 100 liters per minute at 100 kPa from 3 meters. Different pressure, different flow rate, different nozzle size means the tests aren’t equivalent.

NEMA standards test what IP standards don’t, including corrosion resistance testing that runs for more than 1,200 hours and ice formation tests that verify latches and operating mechanisms work when covered in ice. Material and construction requirements ensure long-term durability in harsh environments, which is why real projects fail because of these differences.

Real world scenarios:

A manufacturer installed control panels in a coastal facility and specified IP66 enclosures because IP66 provides excellent protection against water jets, and the initial installation looked perfect. Within 18 months, the panels showed significant corrosion because salt air had compromised the enclosures, and IP66 doesn’t include corrosion testing. The facility spent over $50,000 replacing panels and experienced production downtime during the swap when they should have specified NEMA 4X.

A food processing plant needed new control panels for their production line and specified IP65 enclosures, which protect against low-pressure water jets at 12.5 liters per minute. The plant’s cleaning procedures use high-pressure hoses that deliver water at higher volumes and pressures, so water penetrated the enclosures during the first washdown and damaged the control systems. The plant lost two days of production while emergency repairs were made when they should have specified NEMA 4X or IP66.

An outdoor installation in northern Canada used IP67-rated enclosures because IP67 provides excellent protection against temporary water immersion, and the specifications looked solid on paper. During the winter, ice formed on the enclosure latches and made them impossible to operate and maintenance crews couldn’t access the controls without damaging the equipment. IP standards don’t test ice formation functionality, so the project should have specified NEMA 4X or NEMA 3R, both of which include ice formation testing.

These scenarios repeat constantly because wrong specifications lead to rejected deliveries, budget overruns, premature failures, and operational downtime. The impact isn’t trivial since industry data shows that 18% of industrial equipment failures stem from inadequate water and dust protection.

How to Specify Correctly

Choose NEMA ratings for North American industrial applications, especially when code compliance matters, because NEMA applies when corrosion resistance is critical in coastal facilities, chemical plants, or anywhere with aggressive environmental conditions. Cold weather installations need NEMA ratings because ice formation testing is part of the standard, and insurance companies and customers increasingly require NEMA certification for industrial control systems.

Choose IP ratings for international projects where European or Asian compliance standards apply, because IP works well when high-pressure jet protection is the primary concern and corrosion isn’t a factor. Global supply chains often prefer IP ratings because more manufacturers worldwide test to this standard, and consumer electronics and IT equipment typically use IP ratings regardless of location.

Consider getting both certifications when your company operates globally, when equipment might be exported to multiple regions, or when you need maximum market flexibility. Dual-rated enclosures cost more upfront but eliminate specification conflicts and simplify procurement across different facilities.

Work with control systems integrators who understand both standards by asking specific questions about their experience with each rating system. Verify they hold UL 508A certification for NEMA work and request examples of how they’ve handled rating decisions on projects similar to yours, because the right partner identifies potential specification issues before they become expensive problems.

Getting It Right Matters

These aren’t interchangeable standards with slightly different names but rather systems that measure different things using different test methods for different purposes. NEMA ratings provide comprehensive environmental performance testing including corrosion and ice formation, while IP ratings measure sealing capability against particles and moisture.

Specifying the wrong rating leads to rejected equipment, project delays, premature failures, and budget overruns. Getting it right the first time requires understanding which system applies to your specific application and working with specialists who know both standards. Need help determining which rating your project actually requires? Our team navigates both NEMA and IP specifications daily and can assess your application to recommend the right rating before you finalize your purchase order.

Frequently Asked Questions

Q: Can I use an IP66-rated enclosure instead of NEMA 4X if the water protection specs look similar?

No, because while both protect against water jets, NEMA 4X includes corrosion resistance testing that IP66 doesn’t cover. IP66 will handle the water but may fail quickly in corrosive environments like coastal facilities or chemical plants.

Q: Why does adding the “X” to a NEMA rating increase the price by 25-40%?

The “X” designation requires corrosion-resistant materials like stainless steel instead of carbon steel, plus 2,000 hours of corrosion testing. These material and testing requirements drive the cost premium.

Q: Our facility is in the U.S. but we’re part of a global company. Which rating should we specify?

Specify NEMA for North American code compliance, but consider dual certification if equipment might be transferred internationally or if your procurement team sources globally. Dual-rated enclosures eliminate specification conflicts across regions.

Q: We have high-pressure washdown procedures. Is IP65 enough protection?

Probably not, because IP65 only protects against low-pressure jets at 12.5 liters per minute. Most industrial washdown equipment exceeds this significantly, so you likely need IP66 or NEMA 4X for high-pressure cleaning procedures.

Q: If an enclosure is rated IP67, does that mean it also meets IP66 protection?

Not necessarily, because IP67 tests immersion protection while IP66 tests jet protection, and these are different test conditions. An enclosure needs to be tested and rated for both to guarantee both protections.