What is a SCADA System?

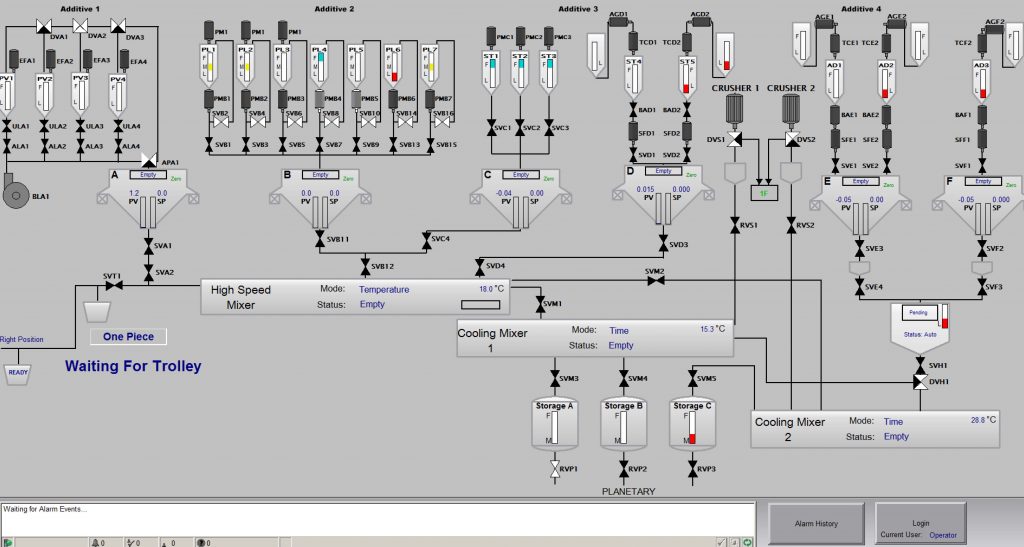

SCADA, or supervisory control and data acquisition, is a comprehensive system comprised of hardware and software components used to monitor and control industrial processes. In SCADA manufacturing environments, these industrial automation controls enable manufacturers to collect and analyze real-time production data, monitor and manage alarms, and program automatic control responses triggered by certain events or system parameters.

Modern SCADA systems serve as the central nervous system for industrial control systems, bridging the gap between field devices and enterprise-level decision making. These systems integrate seamlessly with programmable logic controllers (PLCs) and other automation equipment to create a unified control environment.

Core Functions of SCADA Systems

The essential functions that make SCADA systems invaluable in manufacturing include:

- System monitoring – Real-time visibility into all connected equipment and processes

- Automated control of industrial processes and machines – Sophisticated control algorithms that respond to changing conditions

- Data collection and analysis – Comprehensive data logging and trending capabilities

- Event and Alarm Notifications – Immediate alerts when parameters exceed normal ranges

- Reporting – Detailed production reports and performance analytics

SCADA systems enable the automation of industrial processes and machines that would otherwise be too complex for manual human control. Through the integration of sensors, measuring devices, and other scada components, these systems can detect abnormal parameters or alarms and automatically respond with programmed control functions. For example, if an alarm occurs signaling too much pressure in a line, the SCADA system would trigger a programmed response to open a pressure relief valve to return pressure levels to normal amounts.

SCADA Components and Integration Platforms

Understanding the key scada components is essential for successful scada integration. A typical SCADA system includes:

- Human Machine Interface (HMI) – Operator interface for monitoring and control

- Remote Terminal Units (RTUs) – Field devices that collect data from sensors

- Programmable Logic Controllers (PLCs) – Local automation controllers

- Communication networks – Infrastructure connecting all system components

- Central servers – Data processing and storage systems

- Database systems – Historical data storage and management

There are numerous SCADA platforms available for scada system integration; however, the most popular platforms include Rockwell Factory Talk, Siemens WinCC, Wonderware Systems Platform, and Ignition. Each of these platforms can be programmed with modern web languages such as HTML5, Python, and PHP, and integrated with generalized database software such as SQL.

Professional scada integrators work closely with these platforms to ensure seamless integration with existing industrial automation controls and enterprise systems.

SCADA Manufacturing Applications

Energy-use monitoring and metrics represent a common application for SCADA systems in manufacturing. In this application, the SCADA system helps operators analyze energy use data taken from connected equipment and use that data to cut costs and reduce energy waste.

SCADA manufacturing implementations are also frequently deployed in water/wastewater treatment plants to manage the various stages of water treatment, as well as in food and beverage facilities to optimize production rates and increase product quality. These industrial control systems provide the real-time visibility and control necessary for maintaining consistent product quality while maximizing efficiency.

Industries That Rely on SCADA Systems

Process Solutions has completed scada integration projects for clients across a wide range of industries:

- Food and beverage processing

- Pharmaceutical/Bio-tech

- Water/Wastewater management

- HVAC and commercial building management

- Energy pipelines and utilities

- Seafood processing

- Sorting and fulfillment

- Energy management and refrigeration

Each industry presents unique challenges that require customized approaches to scada system integration, making the expertise of experienced scada integrators essential for successful implementations.

How Can SCADA Systems Help Your Manufacturing Operations?

Implementing a SCADA system in your facility can help decrease production waste and boost overall efficiency by providing useful production insights to operators and management. The information derived from these industrial automation controls facilitates data-driven decisions and leads to increased output, reduced costs, and greater control of your processes.

Another significant benefit of SCADA manufacturing systems is instant notification and automated response to system alarms. With immediate knowledge of issues in the production process, operators and backup systems can respond quicker to reduce equipment downtime and minimize wasted product.

The integration of SCADA systems with existing programmable logic controllers and other automation equipment creates a comprehensive industrial control system that provides unprecedented visibility and control over manufacturing operations.

Professional SCADA System Integration Services

At Process Solutions, we have a team of certified scada integrators and engineers who work with our clients to develop custom systems to match any manufacturing environment. Our expertise in scada system integration ensures that your investment in industrial automation controls delivers maximum value and operational improvement.

Whether you’re looking to upgrade existing systems or implement a completely new SCADA manufacturing solution, our team has the experience and technical knowledge to deliver results that enhance your operational efficiency and profitability.

For more information about SCADA software and scada integration services, or to request a demonstration, please contact us below to discuss your specific requirements.

Frequently Asked Questions

Q: What is the difference between SCADA and PLC systems?

SCADA systems provide centralized monitoring and control across multiple locations, while PLCs handle local automation tasks. SCADA systems often work with multiple PLCs to create a comprehensive industrial control system.

Q: Can SCADA systems work with existing equipment?

Yes, modern SCADA systems are designed to integrate with existing PLCs, sensors, and control equipment. Experienced scada integrators can connect legacy systems with new SCADA components for seamless operation.