With a growing demand for improved green initiatives and manufacturing efficiency, companies such as The United Group are beginning to implement new equipment and systems aimed at reducing waste and their overall environmental footprint.

Process Solutions is uniquely positioned to help these companies improve manufacturing efficiency by designing and building custom control panels, which utilize technologies for operating equipment at optimal speeds and durations, reducing energy consumption and prolonging their useful life. When The United Group, a Puget Sound region recycling conglomerate committed to environmental stewardship, decided to move forward with plans to build a new material recycling facility at their location in Snohomish, WA, they turned to Process Solutions to manufacture the controls to operate the facility’s high-tech sorting system.

Designed in Europe, the sorting system is highly efficient, requires minimal maintenance, and can capture more recyclables from the waste stream, resulting in less reusable materials going to landfills. The United Group’s new facility will feature two of these sorting systems, doubling their material intake capacity while also helping increase their recycling rates, which were already the highest in Western Washington. The sorting system also includes dust filtering screens and water misters to reduce the amount of airborne dust created during material processing.

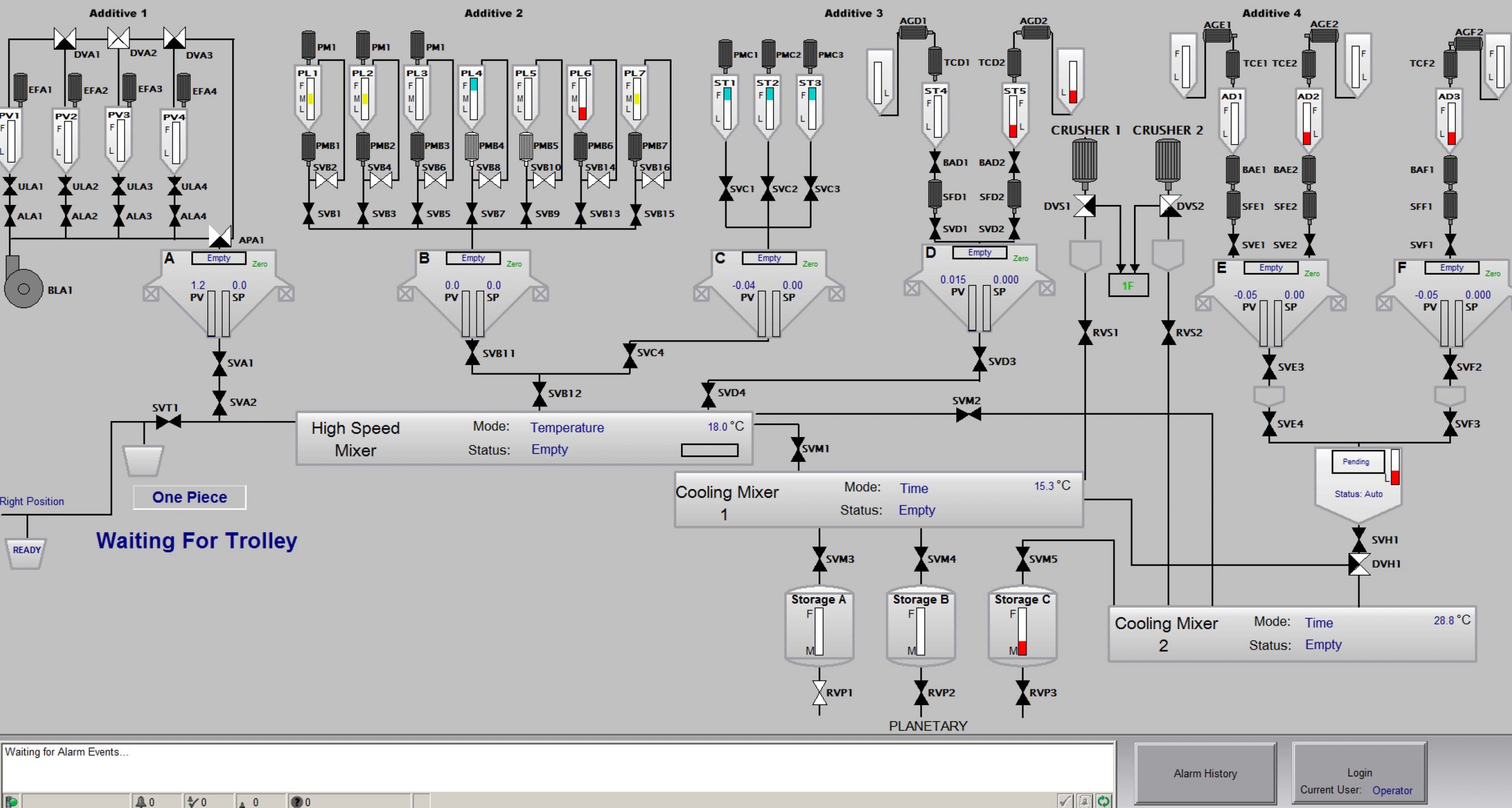

To operate the sorting system, Process Solutions designed and built new controls consisting of a main PLC panel and a separate operator station. The PLC control panel is equipped with (12) variable frequency drives (VFDs) to provide full control over the speed of the sorting system’s feeders, conveyors, and screens. The VFDs also provide motor start-up sequencing, which can reduce the sorting system’s energy consumption by preventing all the motors from starting simultaneously. The main PLC control panel will also operate the sorting system’s band magnets, eddy currents, and air separators, which are devices used for pulling specific recyclables such as metal or drywall out of the waste stream.

In addition, HMIs installed on the control panels will provide real-time alerts for faults, errors, and overloads, as well as display useful information, such as time-run/time-stop, to help operators correct issues and optimize the systems to run at the highest capacity with a consistent flow. The control system also has multiple safety features, including emergency stops, pull stops, and safety disconnects to ensure operator safety.

With a growing demand for improved green initiatives and manufacturing efficiency, companies such as The United Group are beginning to implement new equipment and systems aimed at reducing waste and their overall environmental footprint.

Process Solutions is uniquely positioned to help these companies improve manufacturing efficiency by designing and building custom control panels, which utilize technologies for operating equipment at optimal speeds and durations, reducing energy consumption and prolonging their useful life. When The United Group, a Puget Sound region recycling conglomerate committed to environmental stewardship, decided to move forward with plans to build a new material recycling facility at their location in Snohomish, WA, they turned to Process Solutions to manufacture the controls to operate the facility’s high-tech sorting system.

About The United Group

The United Group is a local, family-owned company, consisting of six divisions, including United Metals, United Recycling & Organics, United Recycling Seattle, Clearview Nursery & Stone, United Construction & Recycling, United Recycling & Container, and KT Recycling & Container. For over 25 years, The United Group has lived out its values of stewardship by taking a holistic approach to recycling and capturing the most reusable materials from waste as possible to create new landscapes, safer roads, cleaner communities, and a healthier planet. Through these values, The United Group is innovating the construction industry with recycled products and leading the recycling industry with the highest diversion rates in Western Washington.

About Process Solutions

Based near Seattle, Washington, Process Solutions is the Northwest’s largest control systems integrator. With a focus on providing industry-leading quality and service, Process Solutions offers a range of control system solutions, including UL control panel design and fabrication, PLC and HMI programming, SCADA integration, industrial refrigeration control systems, and machine monitoring software. Over its 34-year history, Process Solutions has successfully completed thousands of projects for end-users, OEMs, and government entities across industries and applications. With 100 engineers and technicians on staff combined with over 56,000 sq. ft. of engineering and production space, Process Solutions has the capacity and expertise to execute projects of almost any size or complexity.