In 2016, Washington State voters approved measure Sound Transit 3 (ST3), paving the way for one of the country’s most ambitious public transit system expansions. Over the next 25-years, the ST3 program will expand the Puget Sound area’s mass transit network with 62 new miles of light rail, connecting 16 cities between Everett and Tacoma. Servicing these cities will be 28 new stations, including the N150 Roosevelt Station, which is slated to open in Q4 of 2021, with subsequent stations opening every few years until 2041.

To ensure the safety of travelers, each of these light rail stations are being equipped with emergency ventilation (EVS) and building management systems (BMS). In the event of a fire, these systems are programmed to automatically respond by activating large jet fans that redirect smoke to create a safe egress path for passengers. An integrated stairwell pressurization system will also respond to further control smoke and keep routes clear, while the station’s fire alarm and variable messaging systems, which are also included in the BMS, help guide passengers to the safest egress route.

Installed in the new light rail station located in Seattle’s University District, this jet fan directs smoke out of the station, creating a safe egress path for passengers.

To implement the systems at each station, Sound Transit turned to Albireo Energy, a systems integrator located in Redmond, Washington, with expertise in the design, engineering, and integration of HVAC and building management systems. Additionally, Process Solutions was tasked with supporting Albireo Energy on the project by designing and building the control panels to operate the EVS and BMS at each station.

Process Solutions was approached by Albireo Energy to provide support on the ST3 project after demonstrating a high level of quality and expertise on previous projects the companies had worked on together. Process Solutions’ high-volume manufacturing capabilities were also an important factor when being selected for the project, as some of the larger stations can require more than 20 control panels to operate the EVS and BMS.

Over the past 15 years, Albireo Energy has worked closely with Sound Transit on various projects, establishing a proven track record and enabling the companies to work together as a seamless and synergistic team. In addition, Albireo Energy has successfully completed numerous projects across both the Pacific Northwest for applications ranging from a complete network upgrade for a 40-story high-rise building in Seattle, to an HVAC system upgrade that entailed installing 98 digital power meters across the historic 9-acre Pike Place Market district.

As the lead firm overseeing the implementation of the EVS and BMS at each light rail station, Albireo Energy handles all aspects of the design, build, and commissioning of the systems. This includes developing control and network drawings, programming the PLC-based controls that operate the systems, and integrating the new EVS and BMS into Sound Transit’s central SCADA system at their link control center to allow for remote monitoring. Albireo also coordinates with contractors and vendors, such as Process Solutions, to procure the necessary equipment to operate these systems.

For the N150 Roosevelt light rail station, which is set to be the first expansion station to open under the ST3 project, Process Solutions designed and built a total of 26 control panels, consisting of a main PLC panel, a redundant PLC panel, remote I/O panels, interface terminal cabinets, and fan damper control panels. The fan damper control panels operate (3) 450 hp and (2) 350 hp emergency jet fans, which direct smoke away from emergency egress routes. Each of the panels were designed based on specifications provided by Albireo Energy and manufactured in Process Solutions’ production facility in Stanwood, Washington.

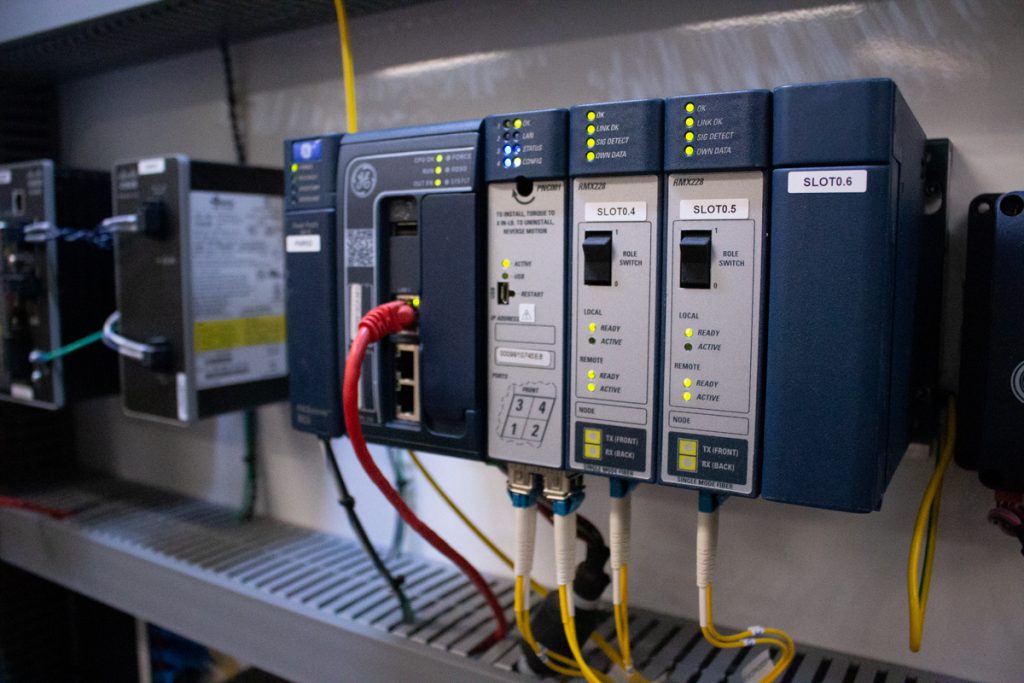

General Electric Rx3i PLC installed in a controls cabinet at the new Sound Transit light rail station in Seattle’s University District.

Operating the entire EVS and BMS systems are a redundant pair of General Electric Rx3i PLCs installed in panels positioned on each side of the station. If the main PLC were to ever malfunction, the redundant PLC can seamlessly take over to prevent disrupting the EVS or BMS. The redundant PLCs and I/O racks are also connected via a ring network with a ring network manager installed to further improve the system’s reliability. If communications between the connected PLCs and I/O racks are broken at one point in the ring, the ring network manager can maintain communications between all devices by enabling the signal to travel in both directions around the ring up to the point of the break.

Through every stage of installation and commissioning of the EVS and BMS, Albireo Energy performs thorough inspections and testing to ensure the systems are safe and reliable. Similarly, Process Solutions performs its own thorough inspections of each control panel to ensure the equipment operating these emergency systems will function properly and reliably when called upon. The result is a proven system that can provide peace of mind to light rail passengers that they will be led to safety in the event of an emergency at any of the newly constructed stations.

Albireo Energy

Albireo Energy is an award-winning systems integrator and leading provider of innovative solutions for building management and industrial control systems. With locations across the United States and abroad, including Seattle, New York, and London, Albireo Energy is able to serve a broad range of industries and applications, such as power generation, water treatment, data centers, healthcare, education, hospitality, transportation, and retail. Albireo Energy’s wide array of capabilities help building owners and managers improve energy efficiency, optimize safety and up time reliability, and reduce operational costs while improving comfort.

Process Solutions, Inc.

Based near Seattle, Washington, Process Solutions is the Northwest’s largest control systems integrator. With a focus on providing industry-leading quality and service, Process Solutions offers a range of control system solutions, including UL control panel design and fabrication, PLC and HMI programming, SCADA integration, industrial refrigeration control systems, and machine monitoring software. Over its 34-year history, Process Solutions has successfully completed thousands of projects for end-users, OEMs, and government entities across industries and applications. With more than 100 engineers and technicians on staff combined with over 35,000 sq. ft. of engineering and production space, Process Solutions has the capacity and expertise to execute projects of almost any size or complexity.