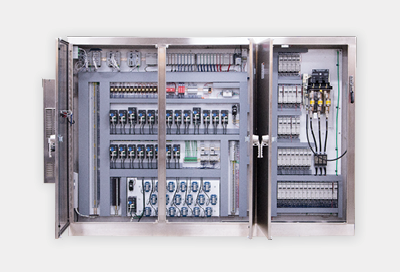

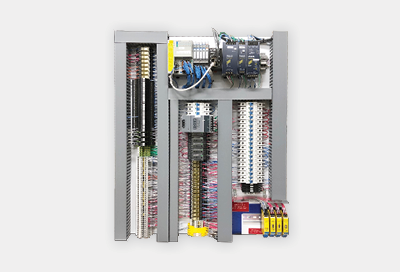

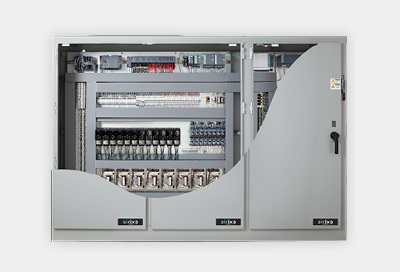

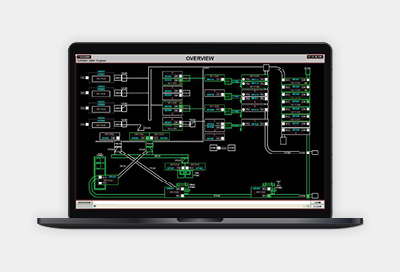

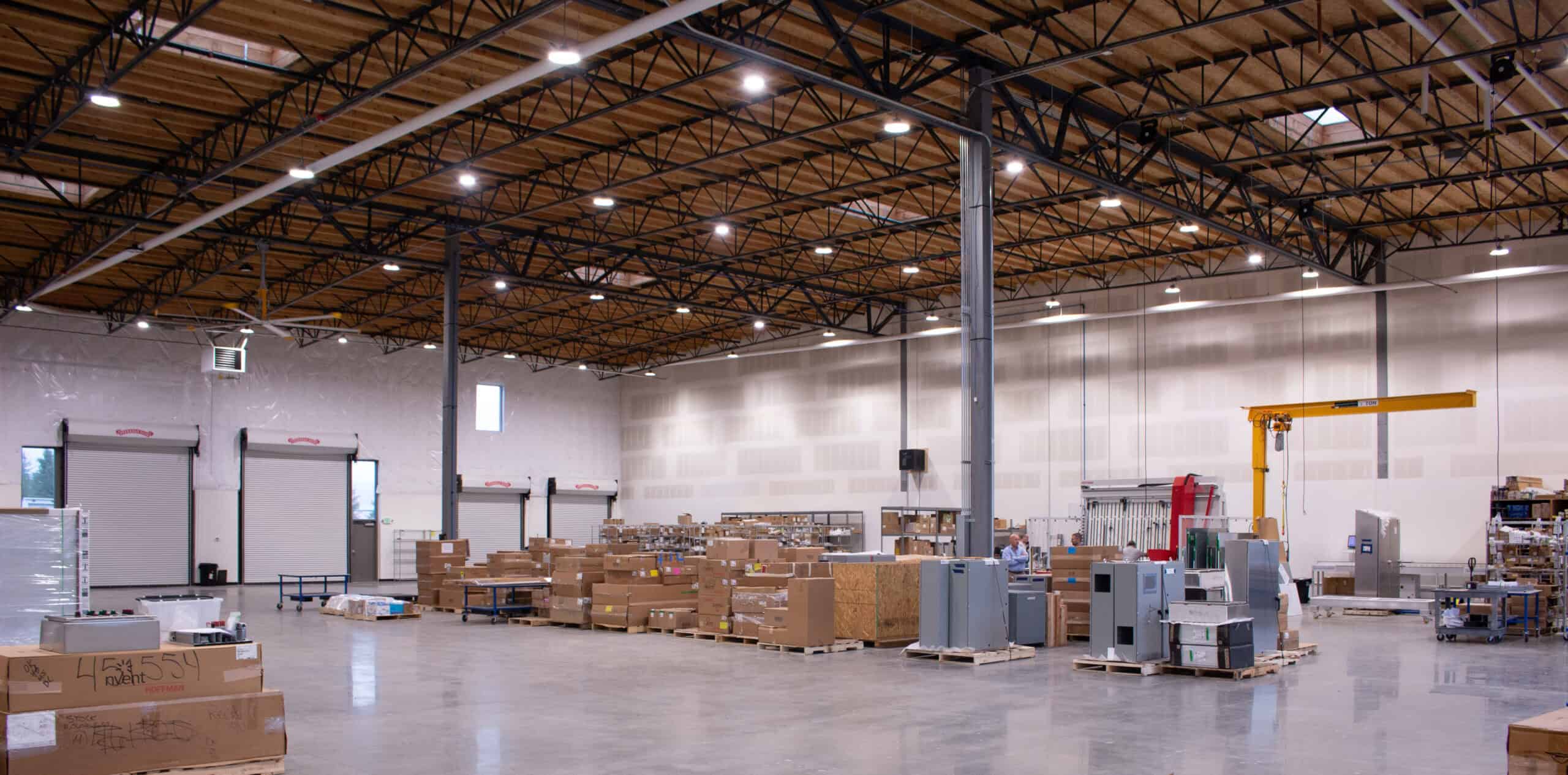

Process Solutions Opens 23,000 Sq.Ft. Control Panel Manufacturing Facility in Arlington, Washington

Process Solutions has acquired a newly constructed 23,000 sq. ft. facility in Arlington, Washington to augment the company’s existing 28,000 sq. ft. manufacturing headquarters in