Process Solutions has acquired a newly constructed 23,000 sq. ft. facility in Arlington, Washington to augment the company’s existing 28,000 sq. ft. manufacturing headquarters in Stanwood, WA, and significantly increase production capacity. In addition to providing more space and flexibility, the new facility is equipped with heavy-duty rigging equipment and specialized tooling to enhance Process Solutions’ production capabilities beyond that of most other panel builders.

Comprised of three connected sections, the new facility features five spacious offices with a fully equipped breakroom café, a large area for crate production, and an expansive manufacturing space that accounts for the majority of the facility’s overall square footage. The facility also features nine dock height loading bays and self-winding electrical cable reels mounted to the ceiling throughout the crate production and manufacturing spaces.

Shipping Crate Production

The crate production area is outfitted with specialized tooling to quickly produce custom, fully enclosed shipping crates for each panel shipment. A vertical panel saw allows for safe and easy ripping of plywood and particle board to make up the floor and walls of the crates, while an automated chop saw provides accurate hands-free cutting of 2×4 and 4×4 lumber for crate framing and runners.

The facility also includes a large area for crate storage and staging, allowing for crates to be built in advance of the ship date to speed up the final crating process when a panel is ready to leave the facility.

Control Panel Manufacturing

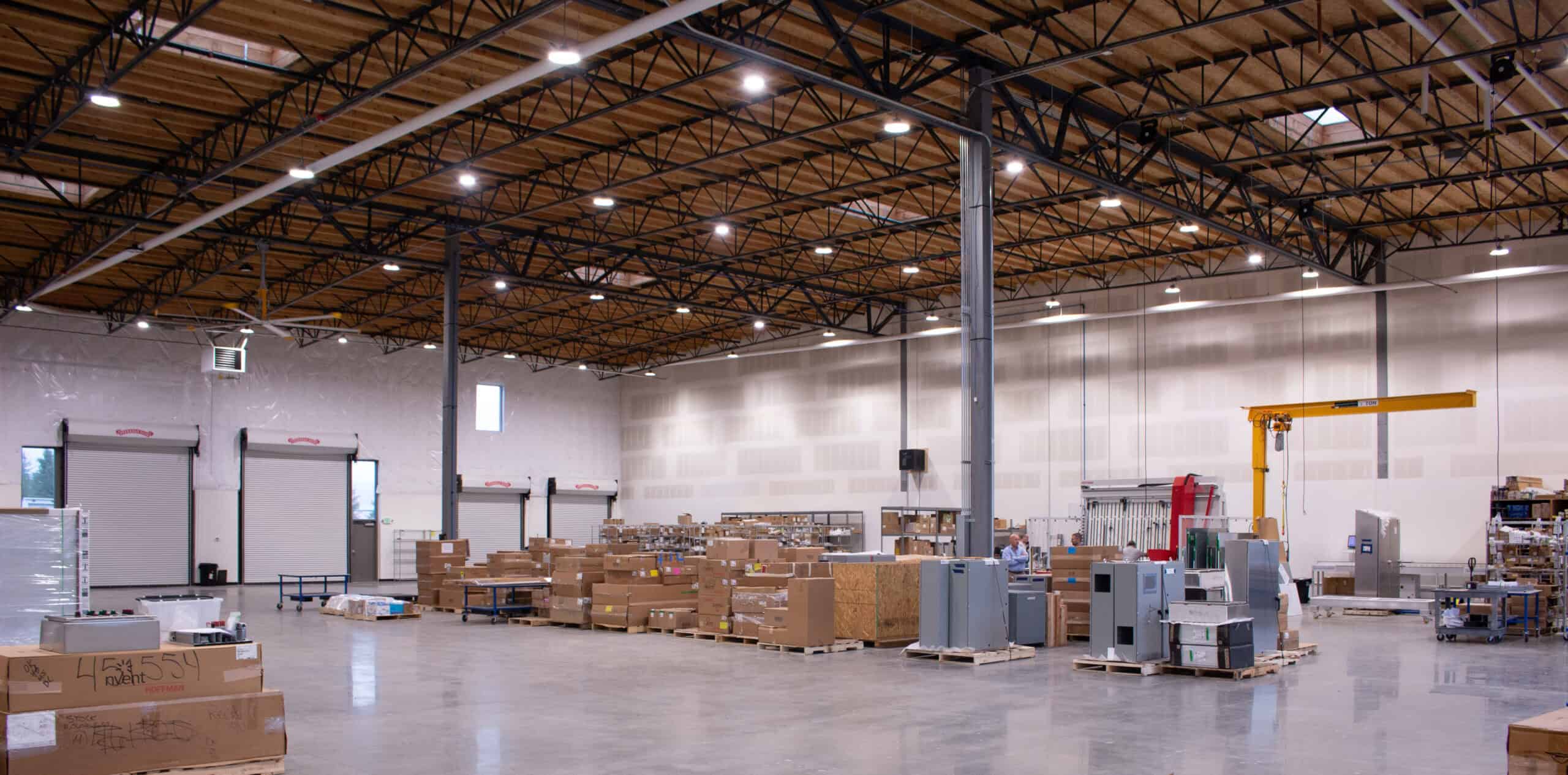

The main manufacturing space is tooled for high volume control panel assembly with heavy-duty equipment, such as a 360° rotating ½-ton crane that allows for moving heavy components and mounting large backpanels into cabinets. Process Solutions also installed a new automated milling machine, doubling the company’s overall backpanel and cabinet milling capacity.

In addition to its tooling, the space also provides a bright and spacious area for control panel assembly and parts storage, relieving pressure on Process Solutions’ Stanwood-based manufacturing center and more than doubling the company’s production capacity.

Overall, Process Solutions’ new control panel manufacturing facility will allow the company to continue its strong rate of growth while providing the necessary capacity and capabilities to continue supporting an expanding client base with industry-leading quality and project efficiency.

About Process Solutions, Inc.

Based near Seattle, Washington, Process Solutions is the Northwest’s largest control systems integrator. With a focus on providing industry-leading quality and service, Process Solutions offers a range of control system solutions, including UL control panel design and fabrication, PLC and HMI programming, SCADA integration, industrial refrigeration control systems, and machine monitoring software. Over its 35-year history, Process Solutions has successfully completed thousands of projects for end-users, OEMs, and government entities across industries and applications. With 100 engineers and technicians on staff combined with over 56,000 sq. ft. of engineering and production space, Process Solutions has the capacity and expertise to execute projects of almost any size or complexity.