Industrial refrigeration systems are critical infrastructure for facilities across food & beverage, biotech, aerospace, and energy sectors. Vapor compression refrigeration systems provide reliable temperature control for product preservation, process cooling, and environmental conditioning in large-scale operations. Understanding how these systems work helps facility managers and engineers make informed decisions about refrigeration solutions that meet their operational requirements.

In this guide, we will explore how a compression refrigeration system works, examine different refrigeration compressor types, and review the four main components that create the refrigeration cycle.

The Vapor Compression Refrigeration Cycle

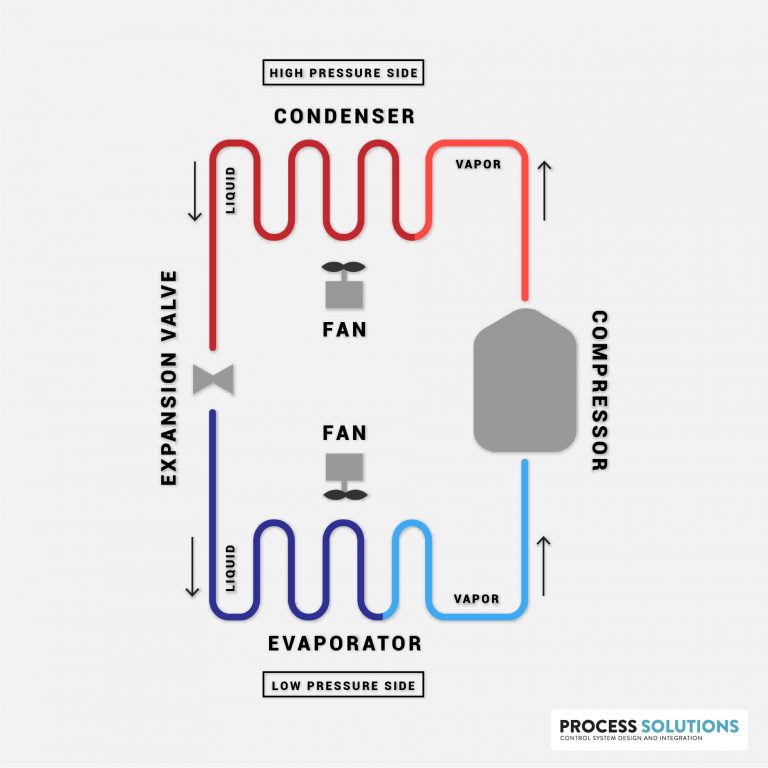

The vapor compression refrigeration system operates by circulating liquid refrigerant through four stages of a closed system. As the refrigerant circulates, it alternately compresses and expands, changing state from liquid to vapor. During these state changes, the system absorbs and expels heat, effectively lowering the temperature of the conditioned space.

Stage 1: Compression

In the first stage of the refrigeration cycle, refrigerant enters a compressor as a low-pressure vapor. The compressor compresses the refrigerant to a high-pressure vapor, causing it to become superheated. Once compressed and heated, the refrigerant leaves the compressor and enters the condensation stage.

Types of Compressors in Industrial Refrigeration

Different refrigeration compressor types serve various industrial applications, each offering specific advantages for different operational requirements:

Reciprocating Compressors:

- Best for smaller to medium-scale industrial refrigeration

- High efficiency at partial load conditions

- Suitable for food processing and cold storage applications

Scroll Compressors:

- Quiet operation ideal for facility environments

- Good efficiency across varying load conditions

- Common in biotech and pharmaceutical cooling systems

Screw Compressors:

- Excellent for large-scale industrial refrigeration

- Continuous operation capability

- Preferred for energy sector and large manufacturing facilities

Centrifugal Compressors:

- High-capacity applications in large industrial facilities

- Energy-efficient for constant high-load operations

- Used in aerospace manufacturing and large data centers

The choice between refrigeration compressor types depends on facility size, load requirements, operating hours, and efficiency priorities.

Stage 2: Condensation

After leaving the compressor, the hot vapor refrigerant enters the condensation stage. The refrigerant flows through a condenser with S-shaped tubes while cool air is blown across the tubes by a fan.

Heat transfers from the tubing to the cooler air because the air temperature is lower than the refrigerant temperature. This heat transfer causes the hot vapor refrigerant to reach its saturated temperature, changing state to a high-pressure liquid. Once in high-pressure liquid state, the refrigerant moves to the metering and expansion stage.

Stage 3: Metering and Expansion

The high-pressure liquid refrigerant enters a metering device or expansion valve. The metering device maintains high pressure on the inlet side while expanding the liquid refrigerant and lowering pressure on the outlet side. During expansion, the liquid refrigerant temperature also reduces.

Stage 4: Evaporation

In a cool, low-pressure liquid state, the refrigerant enters the evaporation stage, where heat removal from the conditioned space occurs.

The cool liquid refrigerant leaves the metering device and enters coiled tubes in an evaporator. Fans blow warm air from the conditioned space across the evaporator coils. The cooler refrigerant in the evaporator coils absorbs heat from the warmer air, reducing the conditioned space temperature.

As the refrigerant absorbs heat, it boils and changes to a low-pressure vapor. The low-pressure vapor returns to the compressor, and the cycle repeats.

Industrial Refrigeration System Considerations

When evaluating vapor compression refrigeration systems for industrial applications, several factors influence system design and performance:

Capacity Requirements: Large facilities require systems capable of handling significant cooling loads while maintaining consistent temperatures across multiple zones.

Energy Efficiency: Industrial refrigeration systems operate continuously, making energy efficiency crucial for operational costs. For industrial applications you’ll also want to consider an energy management system like Airixa to help monitor and optimize energy usage over time.

Reliability and Maintenance: Industrial operations cannot afford extended downtime. System design should prioritize reliable components and accessible maintenance points.

Integration Capabilities: Modern industrial refrigeration systems often integrate with facility automation systems for monitoring, control, and optimization.

Conclusion

Understanding how vapor compression refrigeration systems work helps facility managers make informed decisions about industrial refrigeration solutions. The choice of refrigeration compressor types, system sizing, and integration requirements varies based on specific operational needs in food & beverage, biotech, aerospace, and energy facilities.

Ready to explore how refrigeration control systems can optimize your facility operations? Connect with our refrigeration controls specialist to learn how Process Solutions can help design and integrate reliable cooling solutions for your industrial application.

Frequently Asked Questions

Q: How do I choose between different refrigeration compressor types for my facility?

The choice depends on your facility size, operating hours, and load requirements. Reciprocating compressors work well for smaller operations with varying loads, while screw compressors handle large-scale continuous operations in manufacturing and energy facilities.

Q: What size vapor compression refrigeration system does my industrial facility need?

System sizing depends on your cooling load requirements, facility square footage, and temperature specifications. Large food processing or biotech facilities typically require systems capable of handling hundreds of tons of cooling capacity across multiple zones.

Q: Can industrial refrigeration systems integrate with existing facility automation?

Modern vapor compression refrigeration systems can integrate with SCADA systems, building management systems, and other facility automation through standard communication protocols. This integration enables remote monitoring, automated controls, and energy optimization.

Q: What are the energy efficiency differences between refrigeration compressor types?

Centrifugal compressors offer the highest efficiency for large, constant-load applications, while scroll compressors provide good part-load efficiency. Variable frequency drives can improve efficiency across all compressor types by matching output to actual cooling demand.

Q: How often do industrial refrigeration systems require maintenance?

Maintenance frequency varies by compressor type and operating conditions, but industrial systems typically require quarterly inspections, annual major services, and component replacements every 3-7 years. Proper maintenance prevents costly downtime in critical operations.